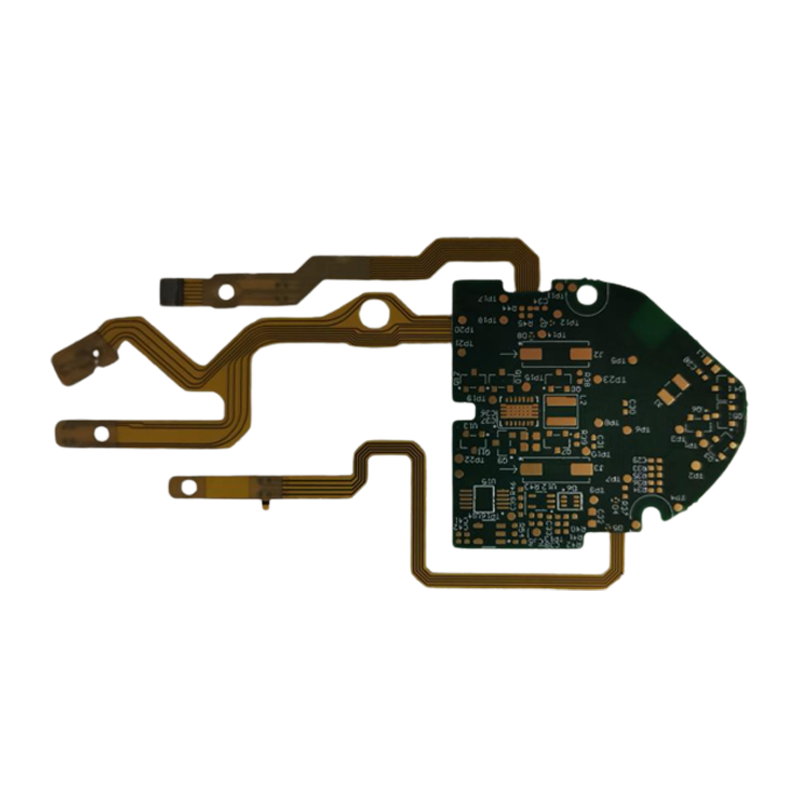

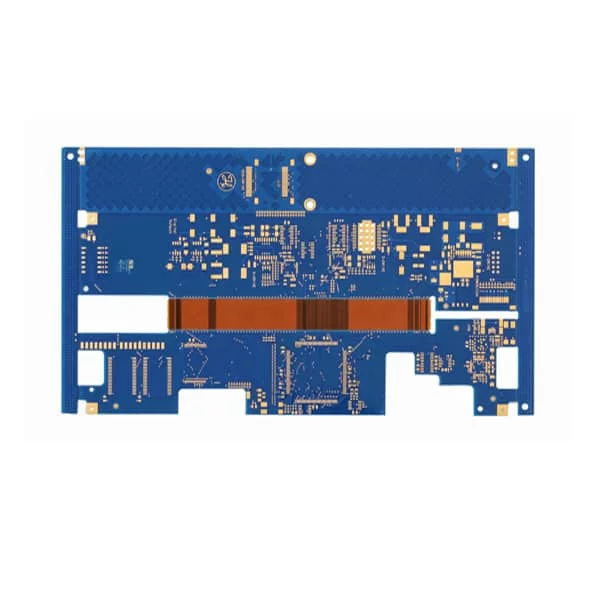

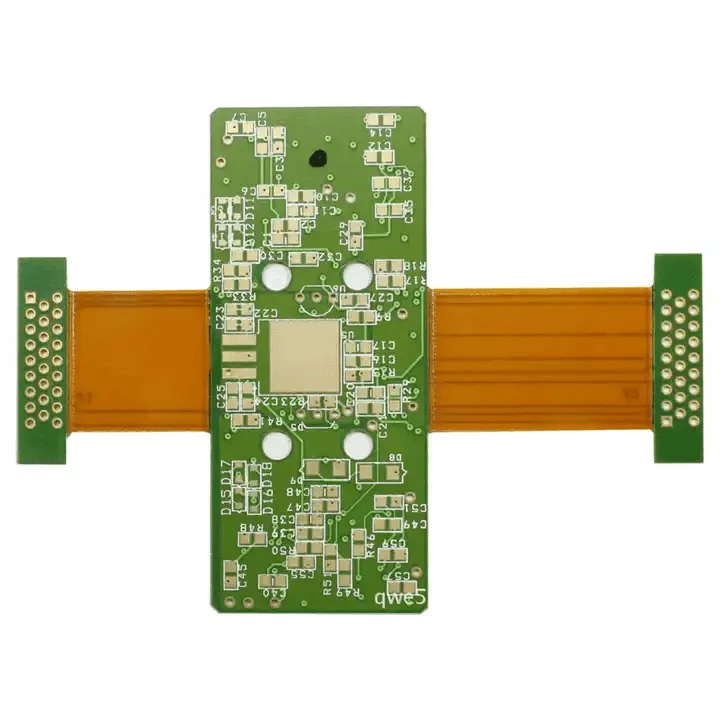

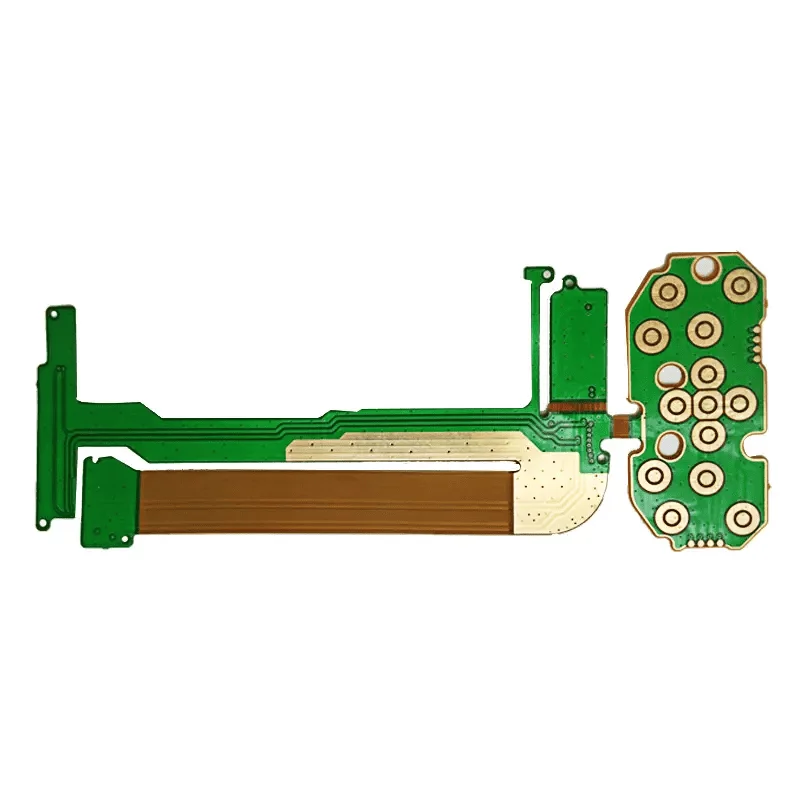

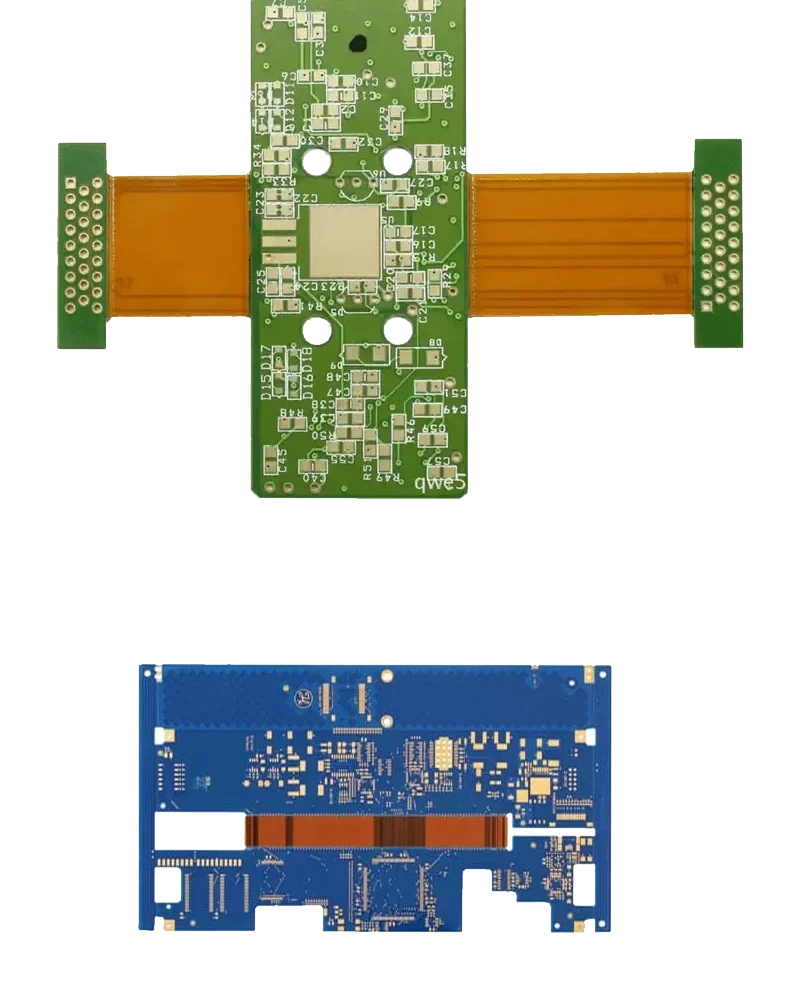

Rigid-flex PCB

| Item | Speci. |

|---|---|

| Layers | 2-14 layers |

| Board thickness | 0.07mm-4.0mm |

| Material | FR-4, High TG, PI,High speed |

| Max panel size | 220*500mm |

| Min hole size | 0.1mm |

| Min line width | 0.05/0.05mm |

| Surface finish | Plated Ni/Au, ENIG, Immersion Tin,Immersion Ag, OSP etc. |

| Copper thickness | 0.5-4oz |

| Soldermask | White, Black, Blue, Green, Red etc. |

| Silkscreen | Red/Yellow/Black/White |

| Min PAD | 5mil(0.13mm) |

| Inter package | Vacuum |

| Outer package | Carton |

| Outline tolerance | ±0.075mm |

| Hole tolerance | PTH:±0.05 NPTH:±0.025 |

| Certificate | UL, IATF16949, ISO, RoHs&Reach |

| Special request | Blind hole+Gold finger + BGA |

| Material Suppilers | Shengyi, KB, Nanya, ITEQ,etc. |

If you have any requirements for PCB/ PCBA/Components, please contact us and we will reply to you as soon as possible!

What Is Rigid-Flex PCB?

In common words, combining flexible board technology with rigid board technology results in rigid-flex printed circuit boards. As rigid-flex boards are designed in a 3D space, they offer greater spatial efficiency. They can also be more challenging than typical rigid design environments. Due to rigid flex’s three-dimensional capabilities, designers are able to twist, fold, and roll flexible board substrates in order to modify the shape for a particular application. Rigid-flex PCB boards are ideal for anyone who needs the flexibility of a soft surface but the durability of a rigid one. With rigid planar surfaces and flexible connections, rigid-flex PCB boards have all the strengths of both types. Read on to find out why they’re becoming increasingly popular within industries that require flexibility, durability, or both!

A Rigid-Flex PCB board is a thin and flexible material like paper, but it has conductive lines that can function as traces in an electronic circuit. These boards are highly specialized and often only made by specialty companies due to the manufacturing process. Rigid-flex boards can provide some interesting advantages and benefits in certain applications. With advances in technology we now have a procedure that is quick and easy as well as inexpensive. It can also be made as creative as you want to be.

The Rigid-flex PCB

There have been many advances and changes in PCBs, and new developments continue to take place. As technology improves, it overcomes challenges and offers more accurate and reliable performance. It is common for PCBs to be rigid, but they cannot be utilized in every device, especially compact ones. That’s how rigid-flex boards come out in market to solve suck issues. In common electronic products, especially mobile phones and laptops, they became common after they were first used in spacecrafts. In reality, it brings together the advantages of rigid and flexible PCBs. By using computer-controlled and latest technology, Rigid-Flex PCBs can be perfectly designed and manufactured at our factory.

Higher Component Density

Higher Quality Control

Longer Life Span

What Are The Advantages Of Rigid-Flex PCB?

Rigid-flex PCB boards are becoming more popular these days due to its advantages over other options. Rigid-Flex boards are flexible, but rigid enough that they can be handled without any issues. These boards are also more reliable than the traditional ones, as it is barely possible for them to bend or bow during assembly. Flexible Rigid-Flexes are even better because they remove the need of having bond wires since the board will be able to bend without breaking apart.

Application Fields We've Served

Computers and Servers

Most commonly used type of circuit board in computers and servers for the manufacture of motherboards, graphics cards, memory modules, and other critical components.

Communication and Networking

Widely used in the communication and networking fields, including the manufacture of routers, switches, base stations, and other communication equipment.

Medical Devices

Can be used to manufacture various medical devices such as diagnostic instruments, therapeutic equipment, monitoring devices, and other medical instruments.

Industrial Control

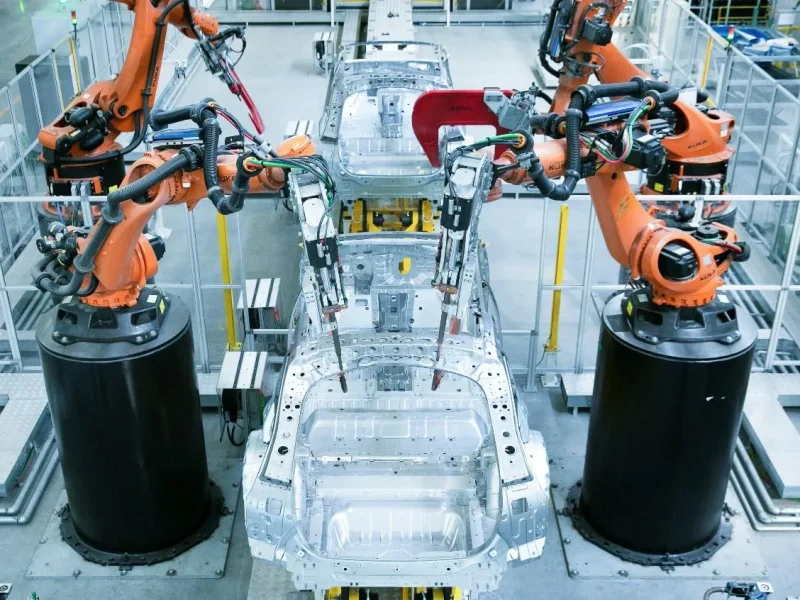

Can be used in the manufacture of industrial control systems, robots, sensors, and other industrial automation equipment.

Automotive Electronics

Widely used in automotive electronics for the manufacture of engine control modules, airbag control modules, in-car entertainment systems, and other vehicle-mounted electronic devices.

Aerospace

Can be used in the manufacture of flight control systems, communication equipment, and navigation systems for aircraft and spacecraft.

Home Appliances

Can be used in the manufacture of circuit boards for TVs, refrigerators, washing machines, and other household appliances.

Consumer Electronics

Commonly used in consumer electronics for the manufacture of circuit boards that require high performance and reliability. such as smartphones, tablets, digital cameras, and other portable electronic devices.

Power & New Energy

Used in power and renewable energy sectors for a range of applications, including production of high-voltage and low-voltage switchgear, transformers, and other components requiring precise wiring and reliable connections.

English

English

中文

中文