PCB & PCBA Testing

At Ucreate International, we provide comprehensive PCB and assembly testing services to ensure that your electronic products meet the highest quality standards. Our team of experienced engineers and technicians can help you with everything from initial design and prototyping to mass production and testing.

Here are several main methods of PCB and PCBA testing

1

Manual Test

Manual Test is to directly rely on visual inspection to confirm that PCBs and their components are thoroughly inspected to ensure product quality.This method is widely used.

However, there are too many components in a complex PCBA, and most of them are very small, so this method is not suitable. Some functional defects are not easy to find and the data is not easy to collect. Therefore, more specialized testing methods are needed.

2

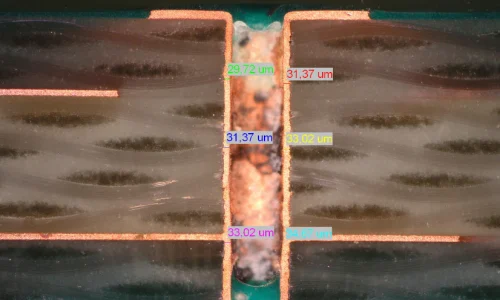

Microsectioning Test

Microsectioning Test ( cross-section analysis) is a destructive sample testing procedure, used throughout the PCB fabrication industry. We make regular microsections each day, as they allow us to see inside the PCB and make precise measurements to check our production processes and to confirm the quality of the finished PCBs.

3

Automatic Optical Inspection (AOI) Test

AOI TEST is a method of automatic inspection of printed circuit boards through optical means, which can be used to quickly detect defects and problems in the manufacturing process of printed circuit boards, avoid errors in product manufacturing, and improve the quality of printed circuit boards.

AOI can be useful for detecting issues early to ensure production is shut down ASAP. However, it does not power up the board and may not have 100% coverage for all part types.

4

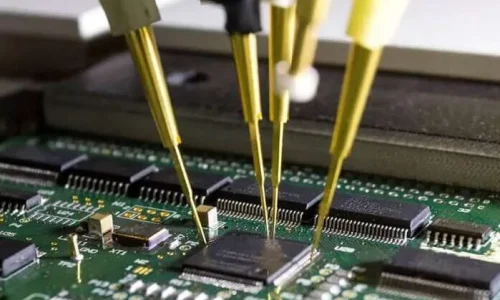

In-circuit Testing(ICT)

ICT, also known as a bed-of-nails test, powers up and actuates the individual circuitry on the board. is used to detect the electronic components and circuit connection performance on the circuit board.

ICT testing can be performed at different stages of the PCB fabrication process. Often performed on bigger connections and ball grid arrays (BGAs).

5

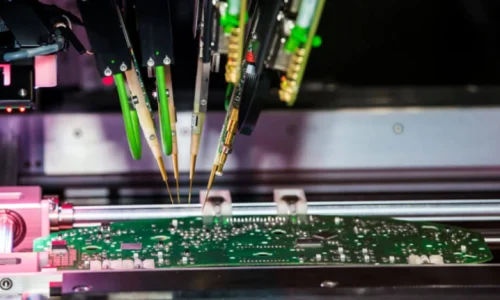

Flying Probe Test

Flying Probe Test uses an automated probe system to test the circuit connections and functions on the PCB. This method of testing does not require expensive test fixtures and programming time, but instead uses probes that can be moved to touch the PCB surface to test the circuit’s connectivity and other parameters.

Automatic optical inspection, also known as automatic visual inspection, is carried out by a special inspection instrument and is used before and after reflow. It has a relatively good effect on the polarity inspection of components and is a common method. But this method is more difficult in identifying a short-circuited PCBA.

6

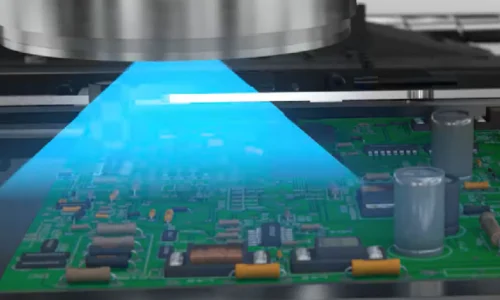

X-Ray Inspection

PCB X-ray inspection, also known as automated X-ray inspection, It is an essential part of the PCB assembly testing process. This testing allows us to identify any defects or issues that may not be visible to the naked eye. We use a range of X-ray inspection techniques, including real-time X-ray inspection (RTXI) and 3D X-ray inspection, to ensure that your product meets the highest quality standards. This technique is widely used in medical and aerospace sectors to find out hidden features and to identify errors such as solder bridges, solder shorts, etc.

7

Function Test

It is a test method for a PCB to verify that its design meets specifications and requirements. Functional testing mainly includes the final product test and the latest entity model (Hot Mock-up).

This functional test and its parameters are usually provided by the customer. Ucreate International can help develop and design such a test.

8

RoHS Testing

English

English

中文

中文