Light-Emitting Diode PCB are an integral part of LED-based lighting systems, serving as the backbone that enables efficient and reliable operation. These specialized circuit boards are meticulously designed to meet the unique requirements of LEDs, ensuring optimal electrical connectivity and effective heat dissipation. In this article, Ucreate International’s production department takes an in-depth look at LED PCB manufacturing techniques and common applications.

What is an LED PCB?

An LED board, also known as an LED printed circuit board, is a special type of PCB designed specifically to house and optimise the performance of Light Emitting Diodes (LEDs). These PCBs are essential components in LED-based lighting systems, providing the necessary electrical connectivity, heat dissipation and mechanical support for the LEDs.

LED PCB Manufacturing Technology

LED PCB manufacturing technology encompasses various processes and considerations to ensure the production of high-quality LED PCBs.

- Material Selection

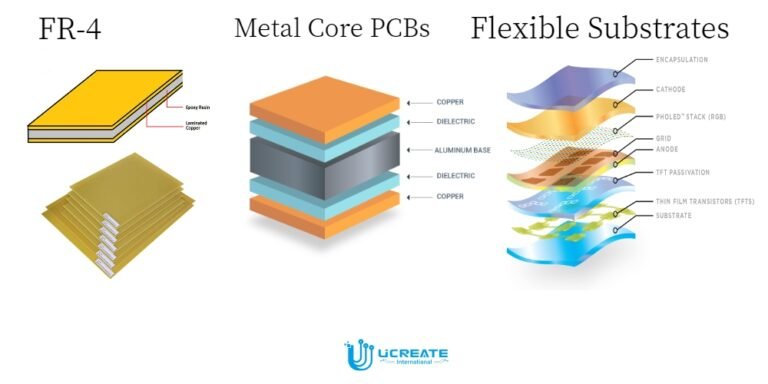

FR-4: This is a commonly used material for LED PCBs due to its cost-effectiveness and widespread availability. FR-4 is a type of fiberglass-reinforced epoxy laminate that offers good electrical insulation properties.

Metal Core PCBs: These PCBs incorporate a metal core, typically made of aluminum, to enhance thermal conductivity. The metal core helps dissipate heat more efficiently, making it ideal for high-power LED applications that generate significant heat. MC PCBs typically have 1-2 layers, but our capability advantage lies in 4-6 layers.

Flexible Substrates: For specialized applications requiring curved or flexible LED board designs, flexible substrates such as polyimide (PI) or polyester (PET) can be used. These materials allow the PCB to conform to specific shapes or fit into tight spaces.

- LED Placement and Soldering Techniques

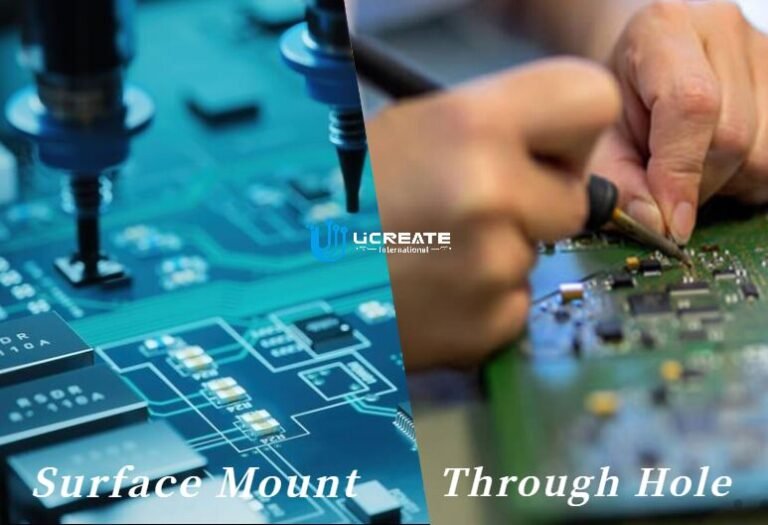

Surface Mount Technology (SMT): This technique involves mounting the LEDs directly onto the PCB surface using solder paste and reflow soldering. SMT allows for precise placement, high-density packaging, and automated assembly processes.

Through-Hole Technology : With THT, LEDs have leads that are inserted into pre-drilled holes on the PCB. They are then soldered on the opposite side of the board. THT is commonly used for larger LEDs, providing mechanical stability and easy replacement if needed.

- Manufacturing Processes

PCB Design: During the design phase, careful consideration is given to component placement, trace routing, and thermal management. The layout and routing of components aim to ensure optimal heat dissipation, electrical connectivity, and signal integrity.

PCB Manufacturing: Once the design is finalized, the PCB can be manufactured through prototyping or mass production. The manufacturing process typically includes techniques such as etching, layer stacking, and copper plating to create the desired circuitry and ensure proper electrical connectivity.

Assembly and Testing: After the PCBs are fabricated, the assembly process begins. This can involve either SMT or THT assembly methods, depending on the LED and PCB design. The LEDs are soldered onto the PCB, and additional components may be added as required. Subsequently, electrical testing and quality control measures are employed to ensure the functionality and reliability of the LED PCBs.

By working together to carefully select materials, apply appropriate LED placement and soldering techniques, and follow precise manufacturing processes, Ucreate International’s various departments can produce LED PCBs with superior performance, reliability and efficiency. These PCBs are key components of LED-based lighting systems, enabling the widespread adoption of energy-efficient and long-lasting LED lighting solutions.

Applications for LED PCB

1. Residential and Commercial Lighting

LED PCBs are widely used in a range of lighting fixtures for residential and commercial spaces. These include:

LED bulbs and tubes: LED PCBs serve as the base for LED bulbs and tubes, providing the necessary electrical connectivity and heat dissipation capabilities.

Downlights and spotlights: LED PCBs are integrated into downlights and spotlights to ensure efficient lighting and long lifespan.

Track lighting and ceiling fixtures: LED PCBs are utilized in track lighting systems and ceiling fixtures, providing reliable and energy-efficient illumination.

2. Automotive Lighting Systems

LED PCBs have revolutionized automotive lighting, offering improved visibility, energy efficiency, and design flexibility. Common applications include:

Headlights and taillights: LED PCBs serve as the foundation for automotive headlights and taillights, enabling brighter and more precise lighting.

Interior lighting: LED PCBs are used for interior lighting in vehicles, including dome lights, map lights, and ambient lighting.

Dashboard displays and indicators: LED PCBs are employed in dashboard displays and indicators, providing clear and vibrant visuals.

3. Display Panels and Signage

LED PCBs are extensively utilized in various types of display panels and signage for both indoor and outdoor applications. This includes:

LED video walls: LED PCBs form the building blocks of large-scale LED video walls used for advertising, entertainment, and information display.

Outdoor and indoor signage: LED PCBs are integrated into outdoor and indoor signs to create eye-catching and energy-efficient displays.

Scoreboards and information displays: LED PCBs enable the creation of scoreboards for sports events and information displays in public spaces.

4. Display Panels and Signage

LED PCBs are extensively utilized in various types of display panels and signage for both indoor and outdoor applications. This includes:

LED video walls: LED PCBs form the building blocks of large-scale LED video walls used for advertising, entertainment, and information display.

Outdoor and indoor signage: LED PCBs are integrated into outdoor and indoor signs to create eye-catching and energy-efficient displays.

Scoreboards and information displays: LED PCBs enable the creation of scoreboards for sports events and information displays in public spaces.

5. Specialized Applications

LED PCBs have found applications in specialized areas that require tailored lighting solutions. Some examples include:

Horticulture lighting for indoor farming: LED PCBs are used in horticulture lighting systems that provide specific light wavelengths for optimal plant growth.

Medical and healthcare lighting: LED PCBs are employed in medical and healthcare settings, such as hospitals and surgical suites, for precise and efficient lighting.

Entertainment and stage lighting: LED PCBs are widely used in the entertainment industry for stage lighting, providing customizable and energy-efficient lighting effects.

LED PCBs continue to drive innovation in lighting technology, enabling energy-efficient and versatile lighting solutions across various industries. As LED technology advances, the applications of LED PCBs are expected to expand further, leading to more efficient and creative lighting solutions in the future.

Conclusion

LED PCBs are crucial components in LED lighting systems, providing efficient electrical connectivity and thermal management for LEDs. They are created through careful material selection, advanced manufacturing techniques, and precise LED placement, enabling the development of high-quality LED lighting solutions. LED PCBs are used in a variety of sectors, including residential and commercial lighting, automotive lighting systems, display panels, and specialized applications such as horticulture and medical lighting. As LED technology continues to evolve, LED board manufacturing will advance, leading to more efficient and innovative lighting solutions in the future.

English

English

中文

中文