When it comes to Printed Circuit Boards (PCBs), choosing the right manufacturer is critical to the success of your project. Ucreate International is a reliable and experienced PCB manufacturer, ensuring the production of high quality PCBs that meet your specifications, cost requirements and delivery schedules. In this article we provide you with our standards. So that you know the most important things to consider when looking for a PCB supplier.

Quality Assurance

Quality assurance is a critical aspect to consider when choosing a PCB manufacturer. Ensuring that the manufacturer follows industry standards and has proper quality control procedures in place is essential for the reliability and performance of your PCBs.

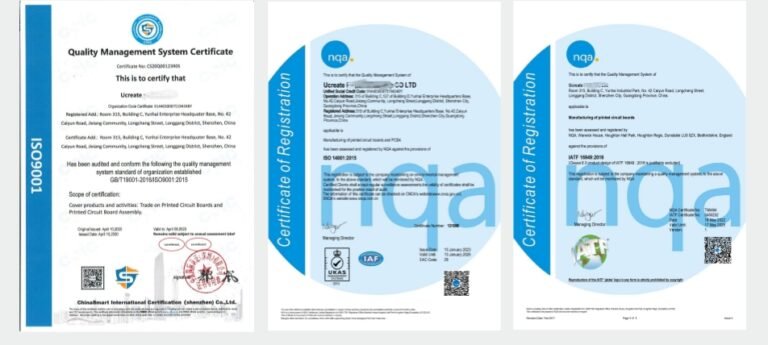

We Ucreate Internaitonal have the follow certifications:

- ISO 9001 is an internationally recognized quality management system standard. It sets out the criteria for a quality management system and requires the manufacturer to demonstrate its ability to consistently provide products that meet customer and regulatory requirements. Look for a manufacturer that is ISO 9001 certified, as this indicates their commitment to quality and continuous improvement.

- IATF16949 certification brings numerous benefits to PCB process quality, including standardization, enhanced customer satisfaction, improved process control and efficiency, effective supplier management, risk management, continuous improvement, and international recognition. Implementing the requirements of IATF16949 helps PCB manufacturers ensure consistent, high-quality products and establish themselves as reliable partners in the industry.

- While ISO 14001 certification may not directly impact PCB process quality, it brings significant environmental and operational benefits that can indirectly contribute to overall process quality, efficiency, and sustainability. By adopting environmentally responsible practices, complying with regulations, optimizing resource management, managing risks, engaging stakeholders, and enhancing corporate image, PCB manufacturers can create a more robust and sustainable operation, which can positively influence process quality in the long run.

Factors in Evaluating PCB Manufacturers’ Quality Assurance Practices

1. Documentation and Processes

Inquire about the manufacturer’s documented quality control procedures and processes. Look for evidence of thorough documentation, including quality manuals, work instructions, and inspection records.

2. Testing and Inspection

Discuss the testing and inspection procedures employed by the PCB and assembly manufacturer. Ensure they have appropriate equipment and facilities for conducting various tests such as electrical testing, thermal analysis, and functional testing.

3. Incoming Component Verification

Ask about the manufacturer’s process for verifying the quality and authenticity of incoming components. Counterfeit or substandard components can have a significant impact on the performance and reliability of the PCBs.

4. Supplier Management

Inquire about the manufacturer’s supplier management practices. A robust supplier evaluation and qualification process ensures that high-quality components are sourced from reliable suppliers.

5. Continuous Improvement

Determine if the manufacturer has a system in place for monitoring and improving their quality control processes. This demonstrates their commitment to ongoing quality improvement and customer satisfaction.

Manufacturing Capabilities

When assessing a printed circuit board provider’s manufacturing capabilities, it is crucial to ensure they align with your project requirements. Here are some factors to consider:

1. Production Volume

Determine if the manufacturer can handle the required production volume for your project. Some manufacturers specialize in high-volume production, while others focus on low-volume or prototype runs. Make sure their production capacity matches your needs. As a leading PCB factory in China, our circuit board production capability is over 20f0000 square meters and EMS assembling capacity at 150,000,000 comonents per month.

2. Board Size

Check if the manufacturer can accommodate the size requirements of your PCB. They should have the capability to produce boards of the desired dimensions, including any specific shape or form factor requirements. The Max Panel Size we can reach is up to “800*1200mm”. We can meet your needs for different sizes of your circuit boards.

3. Layer Count

Evaluate the manufacturer’s expertise in producing PCBs with the required layer count. If your project involves complex designs that require multiple layers, ensure the manufacturer has experience and capabilities in manufacturing multilayer boards.

4. HDI and Complex Designs

If your project involves high-density interconnect (HDI) boards or other complex designs, verify the manufacturer’s capabilities in handling such requirements. Inquire about their experience and equipment for producing intricate PCB layouts, fine-pitch components, and microvias.

Whether you need to make FR4 circuit boards, or HDI, that’s easy case at ucreate international. We specialise in Mainly build volume production & high difficulty PCBs. You can send us your Gerber files to us via email: sales@ucpcba.com, our sales engineer will provide free DFM inspeciotn for you.

5. Equipment and Technology

Inquire about the manufacturer’s equipment and technology infrastructure. Advanced machinery, such as automated assembly lines, precision drilling, and imaging systems, can contribute to higher precision, efficiency, and quality in PCB manufacturing. Ask about their quality control processes and certifications to ensure adherence to industry standards.

We have two PCB factories, one is in Shenzhen and the other one is in jiangxi. We warmly welcome our customers to visit.

Here is the vedio, you may see our factory.

6. Manufacturing Expertise

Assess the manufacturer’s experience and expertise in your specific industry or application. PCB manufacturers who have worked on similar projects or have domain knowledge in your field can better understand your requirements and provide valuable insights or recommendations.

7. Prototyping and Testing

If prototyping is a critical stage in your project, check if the manufacturer offers prototyping services. Additionally, inquire about their testing capabilities to ensure the manufactured boards undergo thorough quality checks, including electrical testing, functional testing, and reliability testing.

Ucreate International provides a complete PCB & PCBA prototyping service. For the quick turn prototype, the fast leading time is only about 24 hours. We promiss 99.9% on-time delivery.

8. Supply Chain Management

Assess the manufacturer’s supply chain capabilities, especially if your project requires specific materials, components, or specialized processes. A well-managed supply chain ensures timely availability of quality materials and minimizes the risk of delays or quality issues.

9. Certifications and Standards

Verify if the manufacturer holds relevant certifications, such as ISO 9001 (quality management system), ISO 14001 (environmental management system), or specific industry certifications (e.g., automotive or aerospace). These certifications demonstrate their commitment to quality, process control, and compliance with industry standards.

10. References and Reputation

Seek references or reviews from the manufacturer’s previous clients to gauge their reputation and satisfaction levels. Online reviews, testimonials, or industry recommendations can provide insights into their track record and customer satisfaction.

You can be assured that Ucreate International has the resources, expertise and technology to meet your project requirements. This assessment process helps reduce risk, ensures a smoother manufacturing experience and increases the likelihood of delivering a high quality PCB that meets your specifications.

Expertise and Experience

When evaluating a manufacturer’s expertise and experience in producing PCBs for your industry or application, consider the following factors:

1. Industry Knowledge

Assess if the manufacturer has experience working in your specific industry or application. Different industries may have unique requirements and standards for PCBs. Working with a manufacturer who understands the specific needs, regulations, and challenges of your industry can be highly beneficial.

2. Portfolio

Review the manufacturer’s portfolio of past projects. Look for examples of PCBs they have produced for applications similar to yours. A diverse portfolio with successful projects in your industry demonstrates their ability to handle specific requirements and deliver quality results.

3. References and Testimonials

Seek references or testimonials from the manufacturer’s previous clients, particularly those in your industry. Feedback from other customers who have worked on similar projects can provide valuable insights into the manufacturer’s expertise, reliability, and customer satisfaction.

4. Collaborative Approach

Assess the manufacturer’s willingness to collaborate and provide technical guidance. A manufacturer with expertise in your industry should be able to offer insights and suggestions to optimize your PCB design, improve manufacturability, and address any specific challenges.

5. Quality Control

Inquire about the manufacturer’s quality control processes and certifications. A manufacturer with a robust quality management system and relevant certifications demonstrates their commitment to delivering high-quality PCBs that meet industry standards and customer expectations.

6. Continuous Improvement

Evaluate the manufacturer’s approach to continuous improvement. An experienced manufacturer should have processes in place to learn from past projects, implement feedback, and enhance their capabilities over time. This focus on improvement ensures that they stay updated with the latest technologies, methodologies, and industry trends.

7. Longevity and Stability

Consider the manufacturer’s track record and stability in the industry. A well-established manufacturer with a long history indicates their ability to adapt to market changes, invest in technology and equipment, and maintain a strong customer base.

8. Customer Support

Assess the manufacturer’s level of customer support. Working with a manufacturer who provides responsive communication, technical assistance, and post-sales support can greatly enhance the overall experience and ensure a successful partnership.

9. Compliance and Certifications

Verify if the manufacturer complies with relevant industry standards and holds certifications specific to your industry. This includes certifications such as ISO 9001 (quality management system) or industry-specific certifications (e.g., medical, automotive, aerospace). Compliance with these standards demonstrates their commitment to quality and adherence to industry-specific requirements.

Working with an experienced manufacturer can help streamline the manufacturing process, reduce risk and increase the likelihood of producing high quality PCBs that meet industry standards and expectations.

Conclusion

It is recommended to conduct thorough research, seek recommendations from industry peers or experts, and request samples or prototypes to assess the manufacturer’s capabilities before making a final decision. Remember that choosing a reliable PCB manufacturer can lead to a successful and long-term partnership, ensuring the quality and reliability of your electronic products.

English

English

中文

中文