Surface-mount technology (SMT), originally called planar mounting, is a method in which the electrical components are mounted directly onto the surface of a printed circuit board (PCB).

It is relative to the traditional THT (Through Hole Technology) “through hole plug-in technology”. The carrier for implementing SMT or THT is a circuit board. “Surface” refers to the pads on the PCB board that can be used for printing solder paste. “Through hole” refers to the plating hole PTH (Plated Through Hole) on the circuit board. SMT patches are more efficient and more efficient than THT plug-ins. Advanced electronic welding technology.

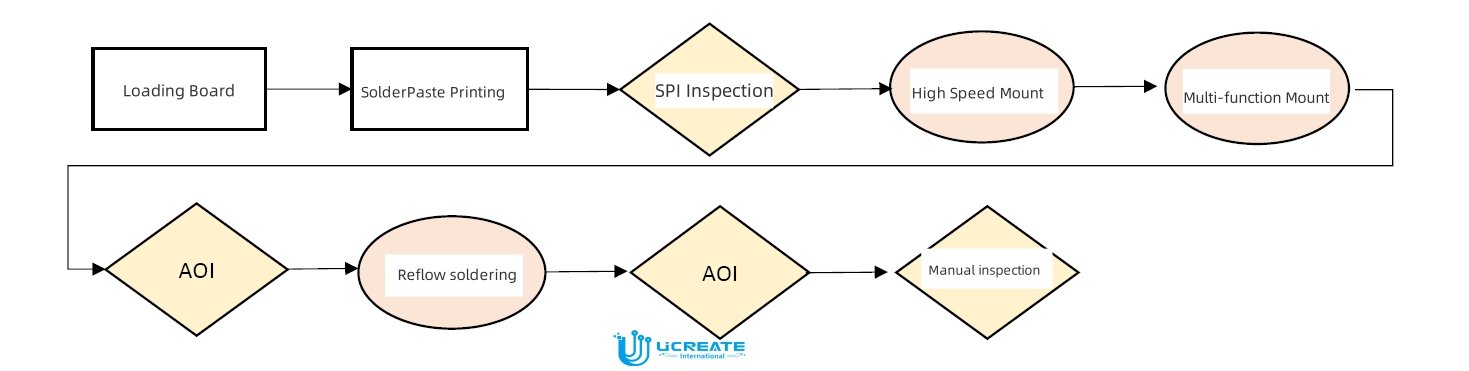

The processing flow chart of SMT is as follows:

We can see that compared to PCB production process and equipment configuration, SMT processing is much simpler. A simple understanding is to print out solder paste and check the printing status of the solder paste, high-speed machine placement of smaller electronic components, multi-function machine placement of larger electronic components, AOI detection of patch status, reflow soldering solidification, AOI furnace Post-inspection and final visual inspection.

Ucreate’s SMT factory is equipped with advanced equipment, such as Desen’s automatic solder paste printing machine, Yamaha’s high-speed and multi-function patch machine, 50% of the employees have more than five years of SMT processing experience and sophisticated testing instruments ,like

kohYoung’s SPI (Solder Paste Inspection Instrument), First Article Inspection Instrument (FAI), accurate and stable AOI and Scienscope’s X-ray machine, etc. The daily patch production capacity of 6 SMT lines can reach 8 million points, and the equipment, instruments and production capacity can fully meet the production and quality requirements of general customers.

SMT patch processing seems simple, but we dare not slack off in quality control. Ucraete Electronics Company mainly ensures the quality of SMT patch processing from the following aspects:

1. Use well-known brands of solder paste, print it with an automatic solder paste printer and test it with a solder paste detector to ensure that 80% of the conventional quality problems in SMT processing are effectively controlled in this link.

2. Use a more advanced first article detector to inspect the first article and issue a first article inspection report.

3. The AOI automatic optical detector detects the pasted components in front of and behind the furnace to ensure that large and small components are not pasted missing, incorrectly pasted, biased or reversely pasted.

4. For BGA PCB boards, use X-ray for random inspection after placement or full inspection according to customer requirements.

The biggest advantage of the SMT machine is that it performs a large number of repeated placement actions, and the labor cost of the Shenzhen SMT factory is increasing day by day. If the patch processing volume of a PCB is large enough, it can be put on the machine and run non-stop for a week.

English

English

中文

中文