Rogers is a well-known PCB board substrate material, providing high-performance substrates for the PCB industry, such as high-frequency, low-loss, high thermal conductivity materials.

How to make a Rogers PCB prototype, here are some simple step-by-step guides:

1. PCB design:

Use CAD software (such as Altium Designer, Eagle, KiCad, etc.) to design your PCB. Make sure your design meets the electrical and physical properties of Rogers materials.

Specify the required Rogers material type, thickness, and copper layer thickness.

2. Select materials:

Choose the substrate that suits your application from Rogers’ material range.

Rogers offers a variety of different types of substrates for high frequency, low loss, high thermal conductivity, etc.

3. Choose a manufacturer:

Look for a manufacturer that can provide Rogers material PCB prototypes.

Make sure the manufacturer has experience and necessary equipment to handle high-performance substrates.

4. Send design files:

Send your CAD design files to the manufacturer and make sure you provide all the necessary files, including Gerber files, BOM (Bill of Materials)

5. Manufacturing and Assembly:

The manufacturer will manufacture the PCB prototype according to your design files.

This may include steps such as board cutting, drilling, copper plating, engraving, soldering, etc.

If necessary, the rogers PCB manufacturer can also provide component assembly services.

6. Testing and Validation:

Once the prototype is manufactured, testing is performed to ensure that it meets the design requirements.

This may include electrical testing, thermal testing, radio frequency (RF) testing, etc.

7. Optimization and iteration:

Optimize and select designs based on test results. If necessary, a new prototype can be re-manufactured for further testing.

8. Production: Once the prototype is verified, mass production can begin. Make sure to communicate with the manufacturer about the production quantity, delivery time and other details.

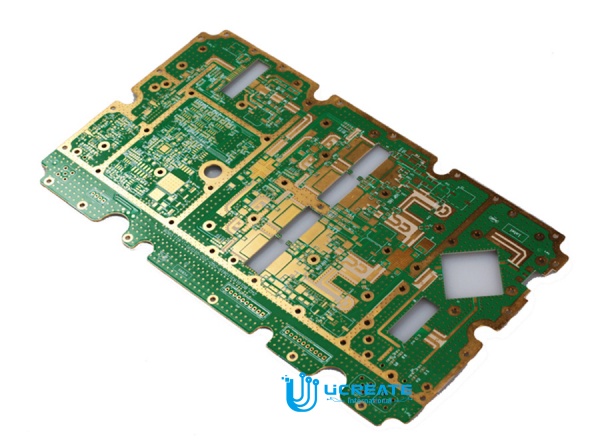

Ucreate rogers PCB manufacture focus on 1-64 layers printed circuit board, we are good at manufacturing various circuit boards with high difficulty and high precision, hard boards, soft boards, hard-flex boards, metal boards, etc.

In addition, please note that the above steps are a simplified guide, and the specific steps may vary depending on the project requirements, the manufacturer’s process and the materials used. Before starting, it is best to have a detailed discussion with your manufacturer to ensure that you understand the details and requirements of the entire process.

English

English

中文

中文