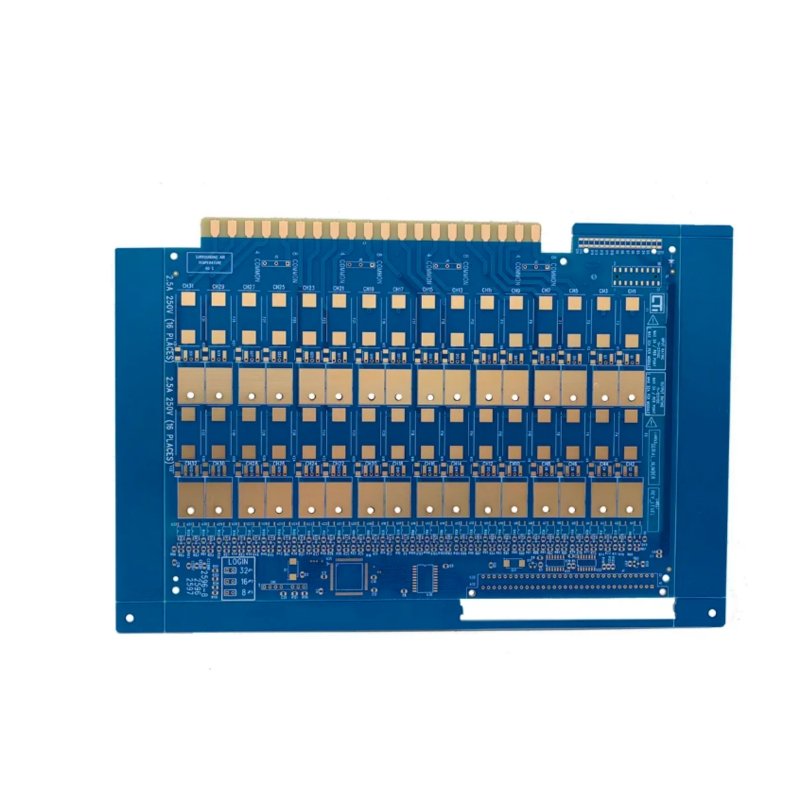

Blue Fr4 ENIG PCB Board

| Layers: | 4 L |

| Material: | Fr4 |

| PCB Thickness: | 1.0mm |

| Cu Thickness: | 1.5OZ |

| Min. Line W/S: | 0.15/0.1mm |

| Surface Finish: | Immersion Gold |

| Application: | Consumer Electronics |

What is ENIG PCB board?

ENIG (Electroless Nickel/lmmersionGold) is a surface finishing process for PCB (Printed Circuit Board). This process plates a layer of nickel-phosphorus alloy on the surface of copper first through a chemical reaction, and then plates a layer of gold on the surface of nickel through a replacement reaction, forming two layers of metal coating.

This surface finishing process can effectively prevent the oxidation and corrosion of copper, improve the solderability and reliability of the PCB.

Advantages

- Wide range of applications: The ENIG process is suitable for a variety of PCB application scenarios, including lead-free soldering, SMT (surface mount technology), BGA (ball grid array) packaging, etc.

- Improve reliability: Through the formation of dense nickel-phosphorus alloy layer and gold layer, can effectively improve the reliability and durability of PCB.

- Environmental protection: ENIG process is a lead-free surface treatment process in line with environmental requirements.

Application

The ENIG is used in a wide range of applications such as data/telecom, high-end consumer products, aerospace, military, high-performance equipment and medical industries. The ENIG process meets the high requirements for reliability, durability, and environmental friendliness of PCBs and provides a superior solution for these applications.

If you have any requirements for PCB/ PCBA/Components, please contact us and we will reply to you as soon as possible!

English

English

中文

中文