When it comes to fan circuit boards, there are two main types: BLDC (Brushless DC) fan PCB and conventional fan PCB. Both have their own advantages and applications. In this article, we will compare the two types and evaluate which one is better suited for different scenarios.

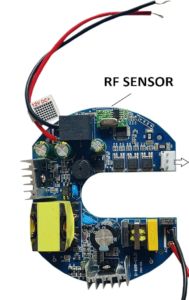

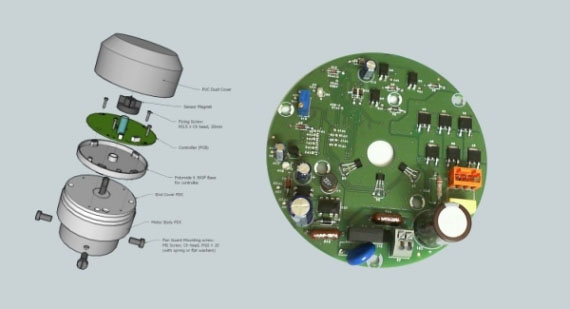

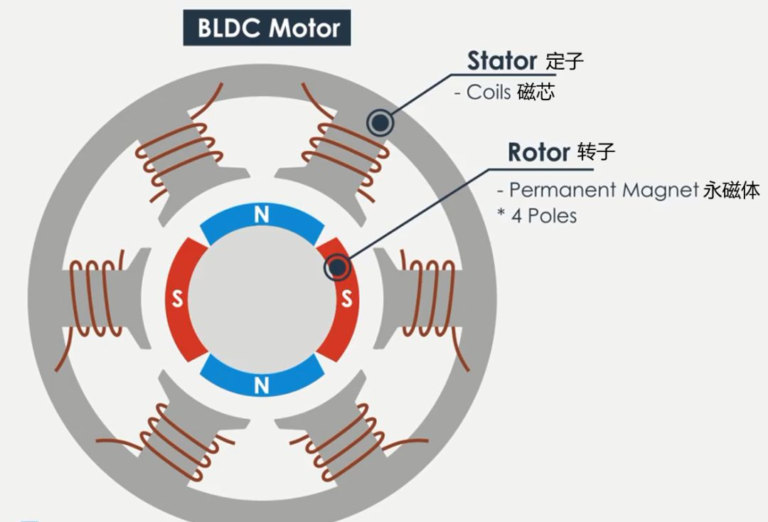

Understanding BLDC Fan PCBs

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

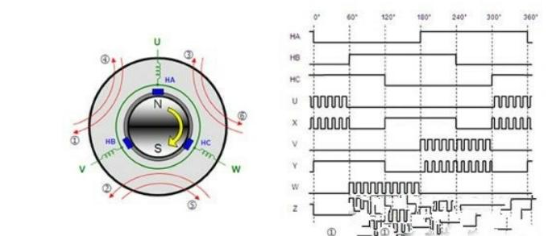

Brushless Design: BLDC fans eliminate brushes and rely on electronic commutation, resulting in improved reliability and reduced maintenance.

Enhanced Efficiency: BLDC fans are more energy-efficient, consuming less power and generating less heat.

Precise Speed Control: BLDC fans offer precise speed control, allowing for optimized cooling and quieter operation.

Reduced Noise and Vibration: The brushless design reduces noise and vibration levels, making BLDC fans suitable for noise-sensitive applications.

Compact and Lightweight: BLDC fans are smaller and lighter, making them ideal for space-constrained applications.

Wide Range of Applications: BLDC fans are used in computer cooling, telecommunications, automotive, aerospace, and industrial automation.

High Efficiency: BLDC fan PCBs consume less power and offer improved energy efficiency compared to conventional fans.

Precise Speed Control: BLDC fan PCBs allow for precise control of fan speeds, enabling optimized cooling performance.

Quiet Operation: BLDC fan PCBs operate at lower noise levels, providing a quieter environment.

Longer Lifespan: The brushless design of BLDC fan PCBs results in increased reliability and longer fan lifespan.

Compact Design: BLDC fan PCBs have a smaller form factor, making them suitable for space-constrained applications.

Reduced Electromagnetic Interference: BLDC fan PCBs generate less electromagnetic interference, minimizing interference with nearby components.

Improved System Cooling: BLDC fan PCBs provide efficient and targeted airflow, ensuring effective cooling of critical components.

Environmentally Friendly: BLDC fan PCBs contribute to energy savings and have a reduced carbon footprint.

Computer Cooling: BLDC fan PCBs are commonly used in desktop computers, laptops, and servers to provide efficient and quiet cooling for processors, graphics cards, and other internal components.

Electronics and Appliances: BLDC fan PCBs find application in various consumer electronics and appliances, such as televisions, refrigerators, air conditioners, and home theater systems, for effective heat dissipation and temperature control.

Industrial Automation: BLDC fan PCBs are utilized in industrial automation equipment, including motor drives, control panels, and power supplies, to maintain optimal operating temperatures and ensure reliable performance.

Automotive Cooling Systems: BLDC fan PCBs are employed in automotive cooling systems, such as radiator fans and HVAC systems, to regulate engine temperature and provide efficient cooling for engine components.

Medical Devices: BLDC fan PCBs are used in medical equipment, such as diagnostic machines, imaging systems, and laboratory equipment, to ensure proper heat management and minimize noise levels.

Aerospace and Aviation: BLDC fan PCBs are suitable for aerospace applications, including aircraft ventilation systems and avionics cooling, where efficient and lightweight cooling solutions are required.

Renewable Energy Systems: BLDC fan PCBs are utilized in renewable energy systems like solar inverters and wind turbines to dissipate heat and maintain optimal operating conditions.

Data Centers: BLDC fan PCBs play a crucial role in data center cooling, ensuring efficient heat removal from servers and networking equipment to maintain stable and reliable operations.

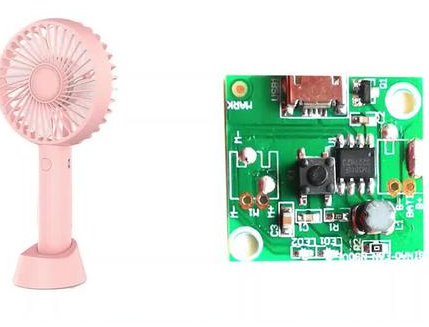

Introduction to conventional fan PCBs

Simplicity: Conventional fan PCBs have a straightforward design and construction, making them easy to manufacture and maintain.

Cost-Effectiveness: Conventional fan PCBs are generally more affordable compared to advanced technologies like BLDC fans, making them a cost-effective choice for cooling solutions.

Speed Control: Conventional fan PCBs offer basic speed control options, often achieved through voltage regulation or simple resistor-based control circuits.

Reliability: Conventional fan PCBs have a proven track record of reliability and longevity in various applications, making them a trusted choice for cooling needs.

Common Applications: Conventional fan PCBs are widely used in personal computers, home appliances (such as refrigerators and air conditioners), industrial equipment, and automotive cooling systems.

Personal Computers: Conventional fan PCBs are commonly used in desktop computers and laptops for cooling the central processing unit (CPU), graphics card, and other internal components.

Home Appliances: Conventional fan PCBs find application in home appliances like refrigerators, air conditioners, and HVAC systems to dissipate heat and maintain proper temperature control.

Industrial Equipment: Conventional fan PCBs are utilized in various industrial equipment, including machinery, control panels, power supplies, and motor drives, to prevent overheating and ensure reliable operation.

Automotive Cooling Systems: Conventional fan PCBs are employed in automotive cooling systems, such as radiator fans and HVAC systems, to regulate engine temperature and provide effective cooling for engine components.

Consumer Electronics: Conventional fan PCBs are used in consumer electronic devices like televisions, audio amplifiers, gaming consoles, and home theater systems to prevent overheating and prolong their lifespan.

Server Rooms: Conventional fan PCBs play a crucial role in cooling server rooms and data centers, ensuring proper airflow and dissipating heat generated by servers and networking equipment.

Medical Equipment: Conventional fan PCBs are found in medical devices, including diagnostic machines, imaging systems, and laboratory equipment, to maintain optimal operating temperatures and prevent component damage.

Performance and Efficiency Comparison

Energy Efficiency:

BLDC Fan PCBs: BLDC fan PCBs are known for their high energy efficiency. The absence of brushes reduces friction and energy losses, resulting in lower power consumption and improved efficiency compared to conventional fans.

Conventional Fan PCBs: Conventional fan PCBs typically have lower energy efficiency compared to BLDC fans. The use of brushes and less advanced control mechanisms can lead to higher energy consumption and lower overall efficiency.

Power Consumption:

BLDC Fan PCBs: BLDC fan PCBs consume less power due to their efficient design and precise speed control. The motor controller adjusts the fan speed based on temperature or system needs, ensuring optimal power usage.

Conventional Fan PCBs: Conventional fan PCBs may consume more power than BLDC fans due to their simpler control mechanisms and fixed-speed operation. They often operate at a constant speed, leading to higher power consumption even when cooling demands are low.

In summary, BLDC fan PCBs excel in energy efficiency and power consumption due to their advanced design, brushless operation, and precise speed control. They consume less power, resulting in improved energy efficiency and reduced operating costs compared to conventional fan PCBs.

Noise Levels:

BLDC Fan PCBs: BLDC fan PCBs operate at lower noise levels compared to conventional fans. The absence of brushes reduces mechanical friction and eliminates the associated noise, resulting in quieter operation.

Conventional Fan PCBs: Conventional fan PCBs may generate more noise due to the presence of brushes and mechanical components. The friction and contact between the brushes and rotor can produce audible noise during operation.

Heat Dissipation:

BLDC Fan PCBs: BLDC fan PCBs offer efficient heat dissipation capabilities. They provide targeted airflow and precise speed control, allowing for optimized cooling of components and effective heat dissipation.

Conventional Fan PCBs: Conventional fan PCBs also contribute to heat dissipation but may be less efficient compared to BLDC fans. Their fixed-speed operation and less advanced airflow control may result in suboptimal cooling performance.

In summary, BLDC fan PCBs excel in reducing noise levels and improving heat dissipation. They operate quietly and provide efficient cooling, resulting in lower noise levels and effective heat dissipation compared to conventional fan PCBs.

Factors Influencing Choice

Energy Efficiency: BLDC fan PCBs are generally more energy-efficient than conventional fan PCBs due to their brushless design and precise speed control. Consider the desired energy savings and operating costs when choosing between the two.

Noise Levels: BLDC fan PCBs operate at lower noise levels compared to conventional fan PCBs due to the absence of brushes. If noise reduction is a priority in your application, BLDC fans may be the preferred choice.

Speed Control: BLDC fan PCBs offer precise speed control capabilities, allowing for customized fan operation based on temperature or system requirements. Conventional fan PCBs typically have fixed-speed operation or limited speed control options.

Cost: Conventional fan PCBs are generally more cost-effective compared to BLDC fan PCBs. Consider your budget and cost constraints when selecting between the two options.

Application Requirements: Assess the specific requirements of your application. If precise speed control, energy efficiency, and low noise levels are critical, BLDC fan PCBs may be more suitable. For simpler applications with lower cost considerations, conventional fan PCBs can be a viable choice.

Longevity and Reliability: BLDC fan PCBs tend to have a longer lifespan and higher reliability due to their brushless design. Consider the desired lifespan and reliability requirements of your application when making a selection.

Thermal Management: Evaluate the heat dissipation needs of your system. BLDC fan PCBs provide efficient and targeted airflow, making them effective for thermal management in demanding applications.

By considering factors such as energy efficiency, noise levels, speed control, cost, application requirements, longevity, reliability, and thermal management needs, you can make an informed decision when selecting between BLDC fan PCBs and conventional fan PCBs.

Energy Efficiency: If energy efficiency is a crucial requirement, BLDC fan PCBs should be considered due to their higher efficiency and lower power consumption.

Noise Sensitivity: If noise reduction is a priority, BLDC fan PCBs are preferable as they operate at lower noise levels compared to conventional fan PCBs.

Speed Control Precision: If precise speed control is necessary, BLDC fan PCBs offer more advanced speed control options, allowing for customized fan operation based on specific temperature or system requirements.

Cost Constraints: If cost is a significant consideration, conventional fan PCBs may be a more cost-effective choice compared to the relatively higher-priced BLDC fan PCBs.

Application Complexity: For more complex applications that require advanced thermal management and precise cooling, BLDC fan PCBs provide better airflow control and heat dissipation capabilities.

Longevity and Reliability: If the project or application requires a longer lifespan and higher reliability, BLDC fan PCBs are generally more durable and dependable due to their brushless design.

System Integration: Consider the compatibility and ease of integration with the existing system or project requirements. Both BLDC fan PCBs and conventional fan PCBs should be evaluated based on their compatibility with the system’s power supply, control mechanisms, and dimensions.

By considering the specific requirements of the application or project, such as energy efficiency, noise sensitivity, speed control precision, cost constraints, application complexity, longevity, reliability, and system integration, you can make a focused and concise decision on whether to choose BLDC fan PCBs or conventional fan PCBs.

Potential advancements in BLDC fan PCBs and conventional fan PCBs

Enhanced Efficiency: There is ongoing research and development to further improve the energy efficiency of BLDC fan PCBs. This includes advancements in motor design, control algorithms, and power management techniques to reduce power consumption and increase overall efficiency.

Noise Reduction: Efforts are being made to minimize the noise generated by BLDC fan PCBs even further. This involves refining bearing designs, optimizing fan blade shapes, and implementing advanced noise cancellation techniques to provide quieter operation.

Intelligent Control Systems: Future advancements may focus on integrating more sophisticated control systems into BLDC fan PCBs. This can include smart sensors, artificial intelligence algorithms, and IoT connectivity to enable dynamic speed control, adaptive cooling, and remote monitoring for optimal performance.

Improved Speed Control: Advancements may be made in conventional fan PCBs to offer more advanced speed control options. This could involve implementing more precise voltage regulation, PWM control, or even incorporating digital control techniques for finer speed adjustments.

Noise Mitigation: Efforts can be made to reduce the noise generated by conventional fan PCBs. This may involve innovations in bearing technologies, fan blade designs, and noise dampening materials to minimize audible noise during operation.

Conclusion

The choice between BLDC fan PCBs and conventional fan PCBs depends on various factors such as application requirements, performance needs, and budget constraints. BLDC fan PCBs offer superior energy efficiency and precise control, making them ideal for applications demanding high performance and low power consumption. On the other hand, conventional fan PCBs are more cost-effective and suitable for simpler cooling applications. By understanding the unique features and benefits of each type, you can make an informed decision based on your specific needs.

English

English

中文

中文