Technical background and core claims

As the core carrier of modern electronic devices, multi-layer PCBs are widely used in communication equipment, industrial control, automotive electronics and other high-end fields.With the increase in functional integration of electronic products, the line density has reached 3/3mil line width pitch level, power density of more than 5W/cm², resulting in a significant local temperature rise (typical value of 80-100 ℃).Ordinary TG130 boards are prone to CTE mismatch in high temperature environments, triggering interlayer peeling and pad floating problems, shortening product life by more than 40%.This contradiction has given birth to the technological breakthrough of medium and high TG plates (TG≥150℃).

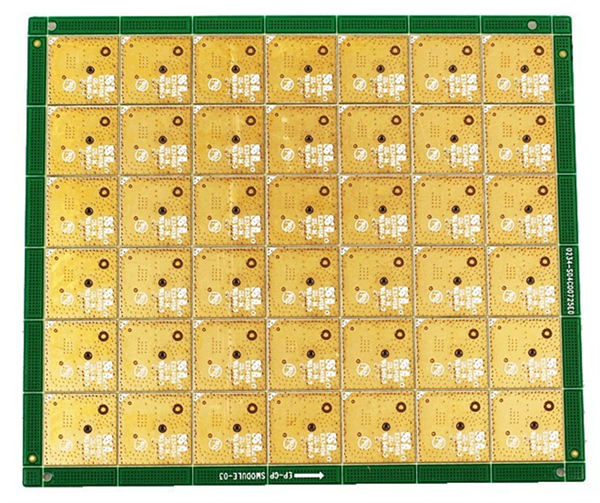

Multi-layer PCBs for high TG board adaptation needs

Thermal Management Challenges

Multi-layer PCBs have a local temperature rise of up to 80-100°C due to dense wiring and high component power density.High TG boards can reduce the interlayer stress by 40% by lowering the coefficient of thermal expansion (CTE ≤ 50ppm/°C), effectively suppressing the risk of plated through-hole copper fracture.Effective experimental data shows that the deformation of TG170 sheet is only 1/3 of that of TG130 sheet in -55℃~150℃ cycle test.

Optimisation of electrical properties

The high TG material has a stable dielectric constant (DK) of 3.5-4.0 (1GHz) and a dielectric loss (Df) of ≤0.005, which is superior to that of ordinary FR-4 (DK=4.5-5.0, Df=0.02).This is critical for high-speed signal (>10Gbps) transmission to reduce signal reflection and crosstalk.For example, insertion loss is reduced by 18 per cent when TG170 boards are used for 8-layer HDI boards.

Process Compatibility

Multi-layer PCB manufacturing involves high-temperature processes (e.g., lamination, reflow) at 200-300°C. The high TG sheet’s glass retention at high temperatures (>2 hours) ensures interlayer alignment accuracy (±0.025mm).At the same time, its low moisture absorption rate (<0.1%) avoids media delamination in hot and humid environments.

Improvement of multilayer PCB performance by high TG boards

- Improved thermal stability: Significantly reduces the risk of delamination in high-temperature soldering processes and enhances the material’s ability to resist deformation, making it particularly suitable for the manufacture of precision multilayer boards.

- Enhanced environmental resistance: Improved resistance to moisture and chemical corrosion, guaranteeing the long-term stability of circuit boards under complex working conditions.

- Optimisation of mechanical properties: Reduce the deformation of materials caused by temperature changes, avoiding signal distortion problems in high-frequency signal transmission.

Typical Application Scenarios and Cases

In the 5G base station amplifier module, the 8-layer board with TG170 sheet reduces the 28GHz band signal loss by 0.8dB/in and the thermal resistance by 25% compared with the TG130 sheet.Measured data of industrial servo driver shows that high TG boards increase MTBF from 5000 hours to 15000 hours.The automotive radar module adopts TG180 sheet with Rogers mixed-press structure, and the temperature rise under 125℃ working condition is 12℃ lower than that of ordinary sheet, which meets the requirements of ISO 16750 standard.

Selection and Design Strategies

- Matching of temperature-resistant grades: Selecting plates with appropriate TG values according to the environment in which the products are used, e.g., high-temperature-resistant grades are required for automotive electronics.

- Structural optimisation design: Give full play to the performance advantages of high TG boards through reasonable layer layout and copper foil thickness control.

- Collaborative process innovation: Combining advanced drilling and lamination processes to break through the technical bottleneck of high-density wiring.

Reasonable selection of high TG boards for multilayer PCB fabrication can ensure product quality and performance to meet the needs of high-tech fields.The synergistic development of multilayer PCBs and high TG boards is the key to respond to the trend of miniaturisation and high power density of electronic devices.With the advancement of material science and manufacturing process, high TG sheet will play a more important role in aerospace, AI chips and other fields, promoting the evolution of electronic systems to higher reliability and stronger environmental adaptability.

English

English

中文

中文