When it comes to PCB (Printed Circuit Board) design and manufacturing, precision is key. Every detail counts, from the choice of materials to the placement of components. Among the numerous techniques used to optimize the functionality and reliability of PCBs, drilling and countersinking are two processes that often get overlooked by beginners but are critical to achieving a high-quality finished product.

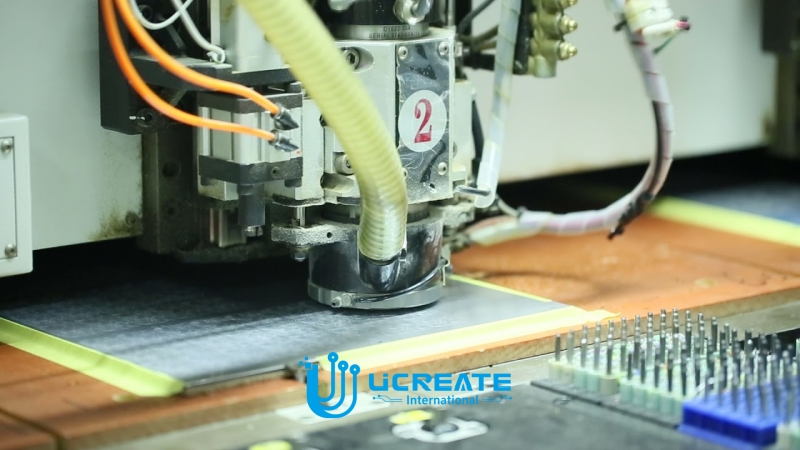

Drilling

Drilling is a fundamental process in circuit board manufacturing, where holes are formed in the circuit board, either mechanically or by laser. These holes can be used for a variety of purposes, including but not limited to.

1.Vias (VIA):This is the most common type of drilled hole and is used to connect copper foils between different layers of a circuit board for electrical connections.

2. Blind vias:Blind vias connect the outermost circuitry of a circuit board to the neighbouring inner layers through plated holes for the linking of the surface layer circuits to the inner layer circuits below.

3. Buried holes:Buried holes are connections between any circuit layers inside the circuit board, but not conducted to the outer layer.

4. Controlled depth holes: controlled depth holes are drilled but not drilled through the circuit board to control a certain depth.

The hole diameter, depth and location of the hole need to be precisely controlled according to the specific design requirements.

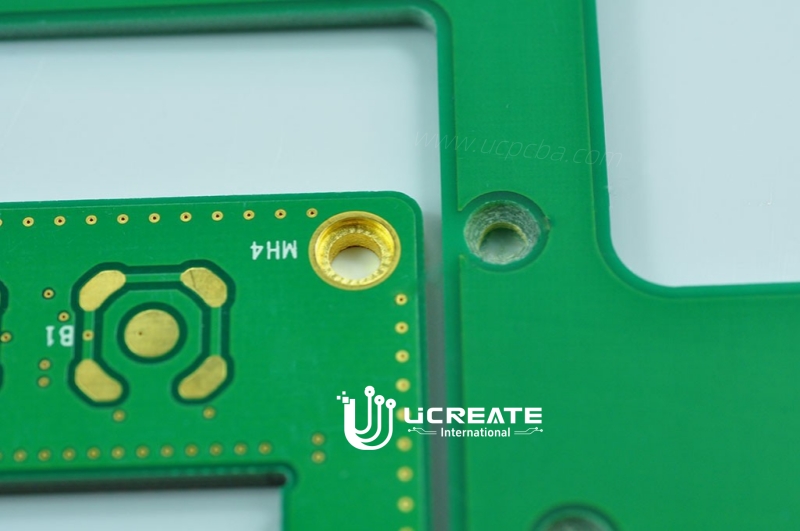

Countersinking

Countersinking is a special drilling technique that creates a stepped or tapered hole in a circuit board for mounting fasteners (e.g., screws) so that the head of the fastener can be countersunk into the hole, flush with or below the surface of the board. The main features and functions of countersunk holes include.

1. Structural features: countersunk holes usually have different diameters of the cross-section, the hole diameter from one end to the other end of the gradual increase in the formation of stepped or conical.

2. Main purpose: countersunk holes are mainly used for the installation of fasteners that require a flat surface, such as flat head screws, cylindrical head socket head cap screws and so on. By countersinking holes, it can ensure that the head of the fastener is flush with the surface of the circuit board to avoid protrusions that affect the appearance and use of the board.

3. Design Requirements: The depth and size of countersunk holes need to be calculated and controlled accurately according to the size of the fastener and the design requirements of the board. Normally, the depth of the countersunk hole should be slightly greater than the head height of the fastener to ensure that the fastener can be completely sunk into the hole. At the same time, the diameter of the countersunk hole needs to be matched with the diameter of the shaft of the fastener, leaving an appropriate gap to ensure that the fixing effect.

Differences

1. Different purposes: the main purpose of drilling holes is to achieve the electrical connection of the circuit board or interlayer connection, while the main purpose of countersunk holes is to provide a flat mounting surface for the fasteners.

2. Different shapes: Drilled holes are usually straight holes or holes with specific shapes (e.g. blind holes, buried holes, etc.), while countersunk holes are stepped or tapered holes.

3. Different applications: Drilled holes are widely used in circuit boards for a variety of connectivity needs, while countersunk holes are mainly used for the installation of fasteners that require a flat surface.

In summary, drilled and countersunk holes have different purposes, shapes and application scenarios in circuit board design. Choosing the right drilling or countersinking technique for a specific design requirement is critical to ensure the performance and reliability of the circuit board.

English

English

中文

中文