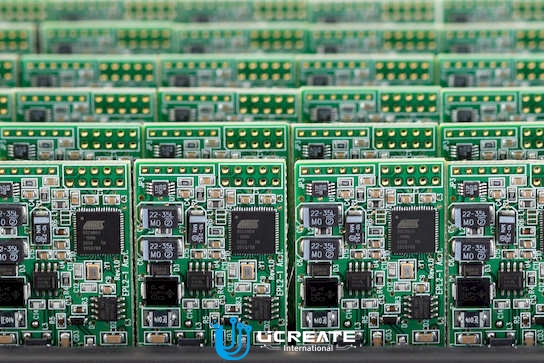

Printed circuit boards (PCBs) are the backbone of modern electronic devices and their production involves complex and specialised processes. At Ucreate International, we provide Electronic Manufacturing Services (EMS) that play a key role in PCB production. We will take an in-depth look at the partnership between PCB designers and us at Ucreate International, as well as the range of services we offer as an EMS provider, focusing on PCB assembly expertise.

In today’s fast paced and competitive electronics industry, PCB designers and EMS suppliers work together to bring innovative and reliable products to market. Collaboration between these two entities is critical to ensure seamless integration of design, manufacturing and assembly processes.

What is EMS?

EMS providers offer a range of services related to the manufacturing and assembly of electronic components, including Printed Circuit Boards (PCBs).

Our EMS services focus on providing end-to-end manufacturing solutions for electronic products. We offer comprehensive services that cover all stages of the production process. These services include design for manufacturability (DFM) consulting, component sourcing, PCB manufacturing, assembly, testing, and sometimes even logistics and fulfillment.

Being an EMS supplier plays a vital role in ensuring the successful implementation of PCB projects. We collaborate closely with PCB designers and customers to transform design specifications into functional and dependable PCBs.

Services Provided by EMS Suppliers for PCB Assembly

1. Overview of PCB Assembly Services

Ucreate International offers a range of EMS services for PCB assembly. Our services ensure efficient and accurate placement of electronic components onto the PCB. We cover all stages of the assembly process, from component preparation to final testing and inspection.

Major PCB assembly services offered include:

(1) Component Procurement:EMS providers have established relationships with suppliers and can source components at competitive prices. They handle the procurement process, ensuring the availability of authentic and high-quality components for the assembly.

(2) Component Preparation:This involves preparing the components for assembly, which may include taping, reeling, or packaging them in the appropriate format. Component preparation streamlines the assembly process and ensures consistent component presentation.

(3) Surface Mount Technology (SMT) Assembly: SMT is a widely used assembly technique that involves mounting components directly onto the surface of the PCB. EMS providers have specialized equipment, such as pick-and-place machines, to accurately place and solder surface mount components onto the PCB.

(4) Through-Hole Assembly: Through-hole assembly involves inserting leads of components through pre-drilled holes on the PCB and soldering them on the opposite side. EMS providers have the expertise and equipment required for precise through-hole component insertion and soldering.

(5) Reflow Soldering: In SMT assembly, reflow soldering is used to permanently attach components to the PCB. EMS companies utilize reflow ovens, which heat the PCB to melt the solder paste and create strong electrical connections between the components and the PCB.

(6) Hand Soldering: For certain components or specialized applications, hand soldering may be necessary. EMS providers have skilled technicians who can perform manual soldering with precision and ensure the integrity of the connections.

2. Surface Mount Technology (SMT) and Through-Hole Assembly

Surface Mount Technology (SMT) and through-hole assembly are two primary methods used in PCB assembly. EMS suppliers are proficient in both techniques and can advise on the most suitable assembly method based on design requirements and component availability.

SMT assembly offers several advantages, including smaller component sizes, higher component density, and improved signal integrity. It is well-suited for complex and compact PCB designs, enabling miniaturization and optimization of space. EMS providers utilize specialized equipment to accurately place and solder surface mount components, ensuring precise and reliable connections.

Through-hole assembly, on the other hand, is suitable for components that require additional mechanical strength or better heat dissipation. It is commonly used for connectors, switches, and larger components. EMS providers have the expertise to insert the leads of through-hole components into pre-drilled holes on the PCB and solder them securely, ensuring robust connections.

3. Quality Standards and Certifications in EMS PCB Assembly

Ucreate International adhere to stringent quality standards and certifications to ensure the production of high-quality PCB assemblies. Some common quality standards and certifications in the EMS industry include:

ISO 9001: This international standard sets criteria for a quality management system, emphasizing customer satisfaction, continuous improvement, and process consistency.

IPC-A-610: This industry standard outlines acceptability criteria for electronic assemblies, defining the requirements for materials, components, and workmanship.

IPC J-STD-001: This standard focuses on soldering processes and requirements for electronic assemblies, ensuring reliable and robust solder connections.

RoHS Compliance: Restriction of Hazardous Substances (RoHS) compliance ensures that PCB assemblies do not contain restricted substances, such as lead, mercury, or cadmium, which are harmful to the environment and human health.

EMS providers strive to achieve and maintain these quality standards and certifications, demonstrating their commitment to producing PCB assemblies that meet the highest industry requirements.

4. Value-Added Services: PCB&PCBA Testing, and Component Sourcing

In addition to PCB assembly, Ucreate Internation offer value-added services that enhance the quality and reliability of the final product. These services include:

Testing: The quality test department performs various tests to ensure the functionality and performance of the assembled PCB. This may include in-circuit testing (ICT), functional testing, boundary scan testing or customised testing based on specific project requirements.

Inspection: We use advanced inspection technology such as 100% Automated Optical Inspection (AOI) and X-ray inspection to detect any manufacturing defects or problems. Inspections help to identify and correct problems.

Conclusion

The collaboration between our EMS suppliers and PCB designers, and the one-stop PCB solutioin services we provide, enable the production of high quality PCBs that meet the unique requirements of each industry. This collaboration paves the way for technological advancement and drives innovation in electronic devices and systems.

English

English

中文

中文