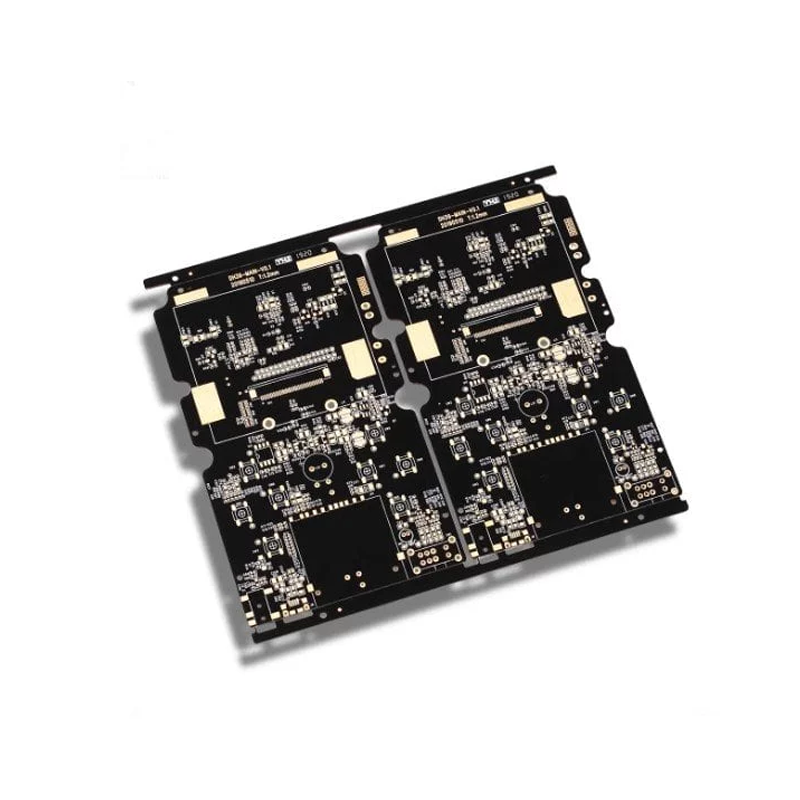

Metal PCB

| Item | Speci. |

|---|---|

| Layers | 1-6 layers |

| Board thickness | 0.6mm-7.0mm |

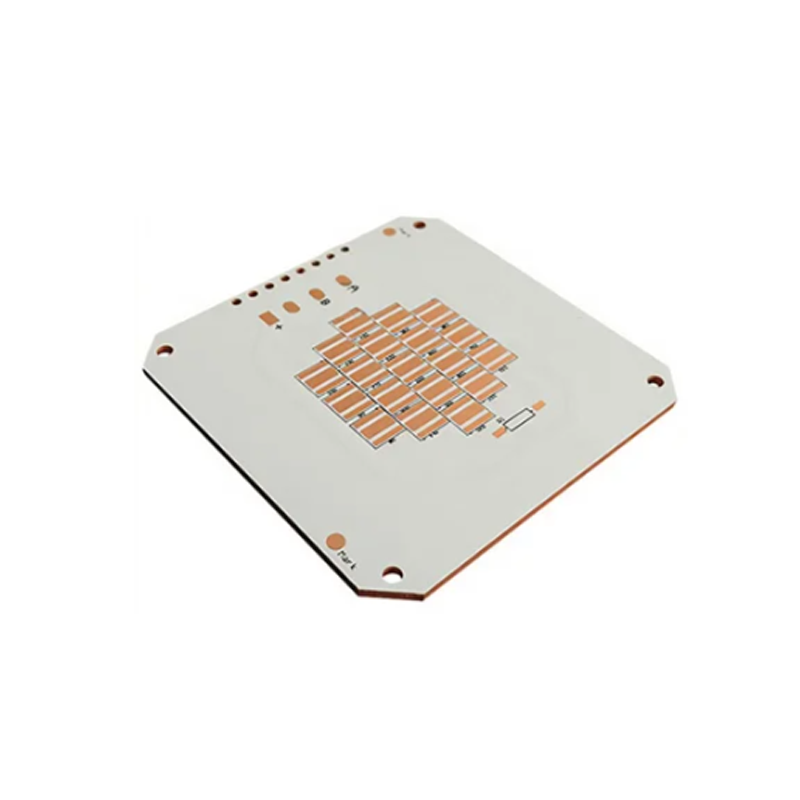

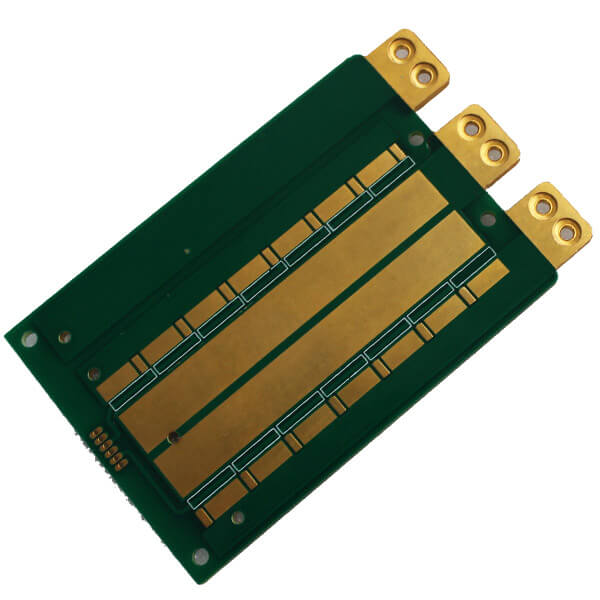

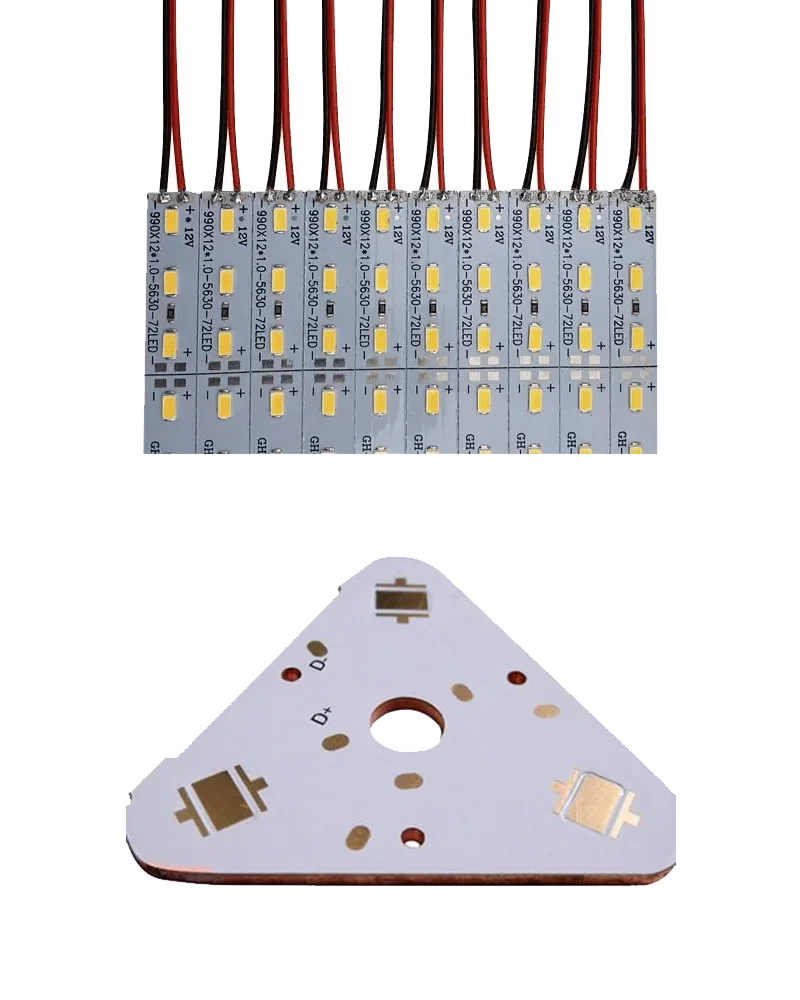

| Material | Al Base, Cu Base, Fe Base, Ceramic Base Tg,Rogers |

| Max panel size | 600*1200mmm |

| Min hole size | 0.075mm |

| Min line width | 2mil |

| Surface finish | HAL(with Pb free), Plated Ni/Au, ENIG, Immersion Tin,Immersion Ag OSP etc. |

| Copper thickness | 0.5-15 OZ |

| Soldermask | Yellow, Red, White, Black, Blue, Green, Grey etc. |

| Silkscreen | Red/Yellow/Black/White |

| Min PAD | 5mil(0.13mm) |

| Inter package | Vacuum |

| Outer package | Carton |

| Outline tolerance | ±0.075mm |

| Hole tolerance | PTH:±0.05 NPTH:±0.025 |

| Certificate | UL, IATF16949, ISO, RoHs&Reach |

| Special request | Blind hole+Gold finger + BGA |

| Material Suppilers | Shengyi, KB, Nanya, ITEQ,etc. |

If you have any requirements for PCB/ PCBA/Components, please contact us and we will reply to you as soon as possible!

What Is Metal PCB?

Metal PCB, also known as metal-core PCB, is a type of printed circuit board that utilizes a metal layer, such as copper or aluminum, as the core material. It is mainly used in high-performance and high-power electronic applications.

The metal layer in Metal PCB serves as the primary conductor layer, providing high electrical conductivity. It is typically sandwiched between layers of dielectric material, which provide electrical insulation and support for the circuit traces. The assembly of these layers is then laminated together under high pressure and temperature to form the metal PCB.

Advantages of Metal PCB

Metal PCB offers several advantages over traditional fiberglass-based PCBs:

- Enhanced Thermal Performance: Metal PCBs have a high thermal conductivity, allowing for effective heat dissipation and improved reliability. This is particularly useful in high-power applications where heat management is critical.

- Improved Electrical Performance: Metal PCBs provide excellent electrical conductivity, resulting in lower resistance and improved signal transmission quality.

- Enhanced Mechanical Strength: The metal layer in Metal PCBs provides additional structural support, resulting in a more robust and durable circuit board.

- Simplified Assembly: Metal PCBs can be easily integrated into metal-based enclosures or chassis, providing a seamless and streamlined assembly process.

Application of Metal PCB

Application Fields We've Served

Computers and Servers

Most commonly used type of circuit board in computers and servers for the manufacture of motherboards, graphics cards, memory modules, and other critical components.

Communication and Networking

Widely used in the communication and networking fields, including the manufacture of routers, switches, base stations, and other communication equipment.

Medical Devices

Can be used to manufacture various medical devices such as diagnostic instruments, therapeutic equipment, monitoring devices, and other medical instruments.

Industrial Control

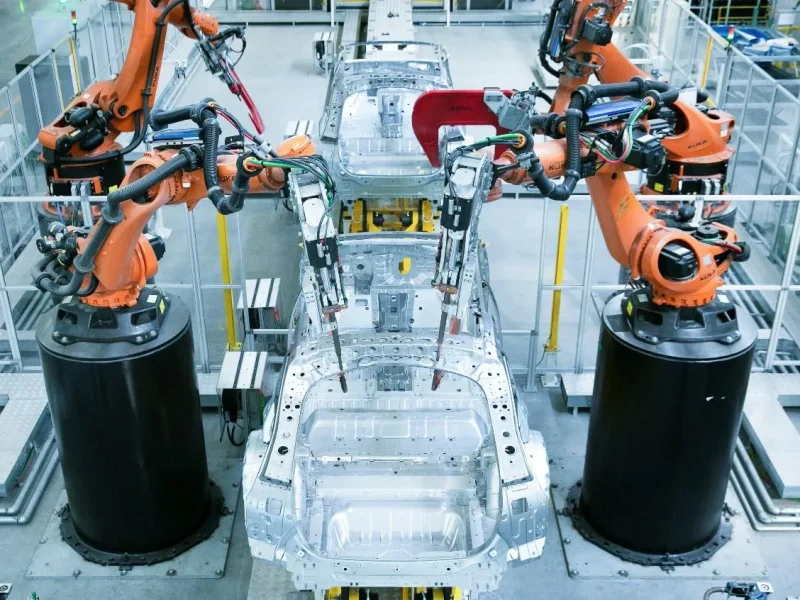

Can be used in the manufacture of industrial control systems, robots, sensors, and other industrial automation equipment.

Automotive Electronics

Widely used in automotive electronics for the manufacture of engine control modules, airbag control modules, in-car entertainment systems, and other vehicle-mounted electronic devices.

Aerospace

Can be used in the manufacture of flight control systems, communication equipment, and navigation systems for aircraft and spacecraft.

Home Appliances

Can be used in the manufacture of circuit boards for TVs, refrigerators, washing machines, and other household appliances.

Consumer Electronics

Commonly used in consumer electronics for the manufacture of circuit boards that require high performance and reliability. such as smartphones, tablets, digital cameras, and other portable electronic devices.

Power & New Energy

Used in power and renewable energy sectors for a range of applications, including production of high-voltage and low-voltage switchgear, transformers, and other components requiring precise wiring and reliable connections.

English

English

中文

中文