PCB Fabrication

Rigid PCB

A rigid printed circuit board (PCB) is a rigid board made of fiberglass and copper that provides a stable and reliable electronic interconnection solution. It is widely used in various electronic devices due to its high reliability, low cost, and ease of manufacturing.

Flex PCB

A flexible printed circuit board (Flex PCB) is a thin, flexible, and bendable circuit board that allows for high-density electronic interconnections in confined spaces. It provides a cost-effective and space-saving solution for electronic devices that require flexibility and portability.

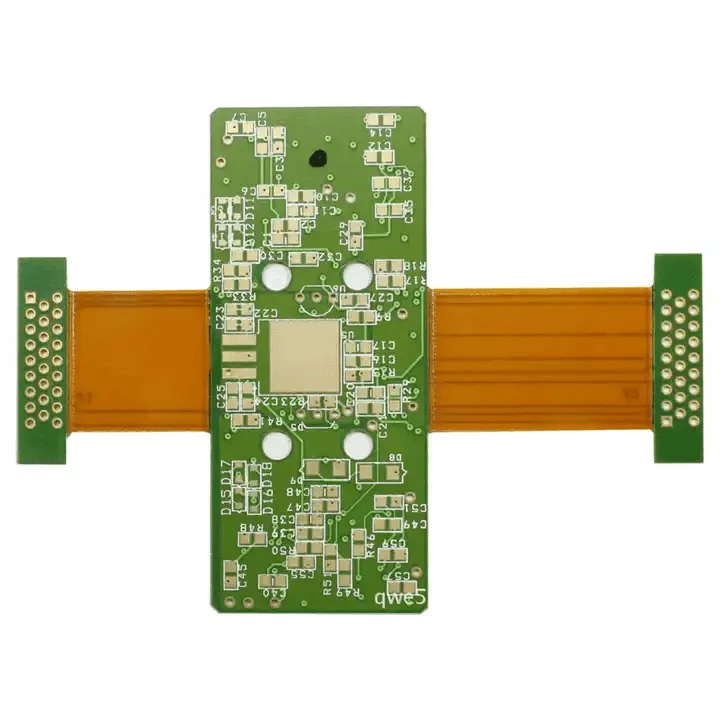

Rigid-flex PCB

A rigid-flex printed circuit board (Rigid-Flex PCB) combines the rigid and flexible properties of PCBs to provide a unique electronic interconnection solution. It consists of rigid sections that provide structural support and flexible sections that allow for bending and flexing in confined spaces.

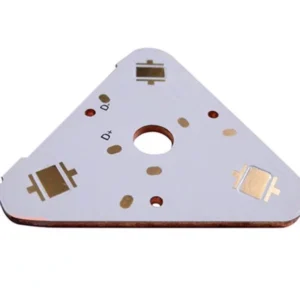

Metal PCB

A metal-core printed circuit board (Metal PCB) utilizes a metal layer, such as copper or aluminum, as the core material for the circuit board. This type of PCB provides enhanced thermal conductivity, improved electrical performance, and higher stiffness compared to traditional fiberglass-based PCBs.

Low Volume PCB Fabrication

A printed circuit board is a flat laminated composite made from a non-conductive substrate material with a copper layer buried beneath its outer surface. Copper plates or substrates can be cut to reveal the design depending on the requirements. In designing and manufacturing multilayer printed circuit boards, additional steps are required to take into account the additional layers. Printed circuit boards with multiple layers use thin single circuit boards and a layer between them that are connected to create an entire circuit board. Multi-layer circuit boards are manufactured using a multi-layer printing process that utilizes layers such as composite layers, copper foil layers, and insulation layers.

- Single-layer PCB Fabrication

- Double-side PCB Fabrication

- Multi-layer PCB Fabrication

Since the purpose of a printed circuit board prototype is to test the actual layout of the system, it is acceptable to use a different manufacturing process for small quantities of printed circuit board prototypes.

- Rigid PCB Prototype

- Flex PCB Prototype

- Rigid-flex PCB Prototype

- Metal PCB Prototype

Why Choose Us?

Ucreate International is a high-tech company focusing on PCB Manufacturing, PCB Assembly and Cоmроnеntѕ Sоurсing Sеrviсе more than 20 уеаrs.

We dedicate to produce various types of printed circuit boards , mainly include single-sided, double-sided, multilayer circuit boards, high precision HDI, flexible boards (FPC), rigid-flexible boards (including HDI) ,metal circuit boards and their SMD plug-ins. Our monthly production capacity reaching over 5,000 models, 200,000 square meters and EMS assembling capacity at 150,000,000 components .

Advanced Technology

✓ HDI ✓ Hard Gold Board ✓ High Frequency Board ✓ Cooper-base Board ✓Ceramic Substrate board ✓Transparent FPC

Professional Advices

Our engineer will provide suggestions on customer's designs and help to improve Gerber's design from the manufacturing process perspective.

Diversified Raw Material

We can supply a wide variety of raw materials,such as Fr-4(TG130~TG170)/IT180A/CME1/CEM3/Rogers/ISOLA/PI materials/Metal materia,High TG,High Speed,High Frequency,High Thermal Conductivity etc.

Quality Control Process

In the whole production,we will perform 3 times quality testing: materials testing,semi-finish testing,finished-item testing.

24/7 After-Sale Services

We take responsibility for every item we provided to our customers.We guarantee that we take care of every issue from our client.

Send Your PCB Files Or BOM List Now!

Talk to us to get solution for your project, we will provide you best recommendations for easy manufactuing and cost saving.

English

English

中文

中文