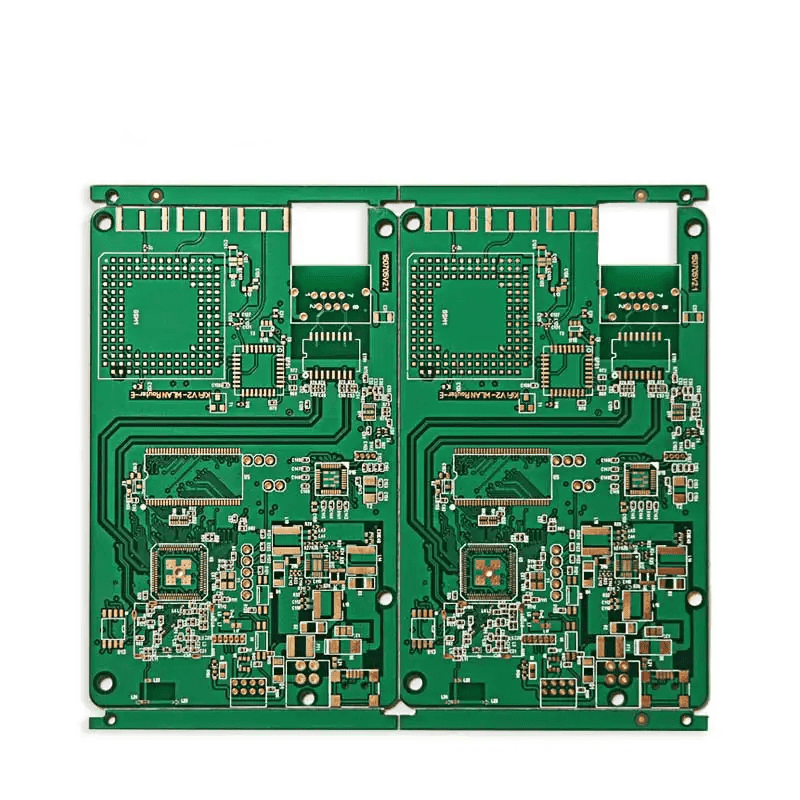

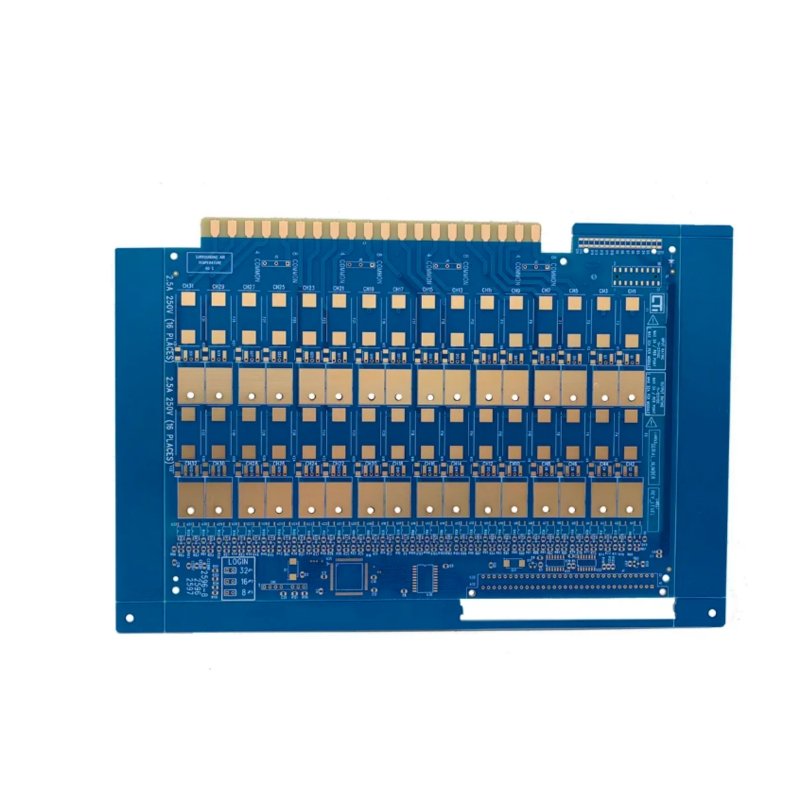

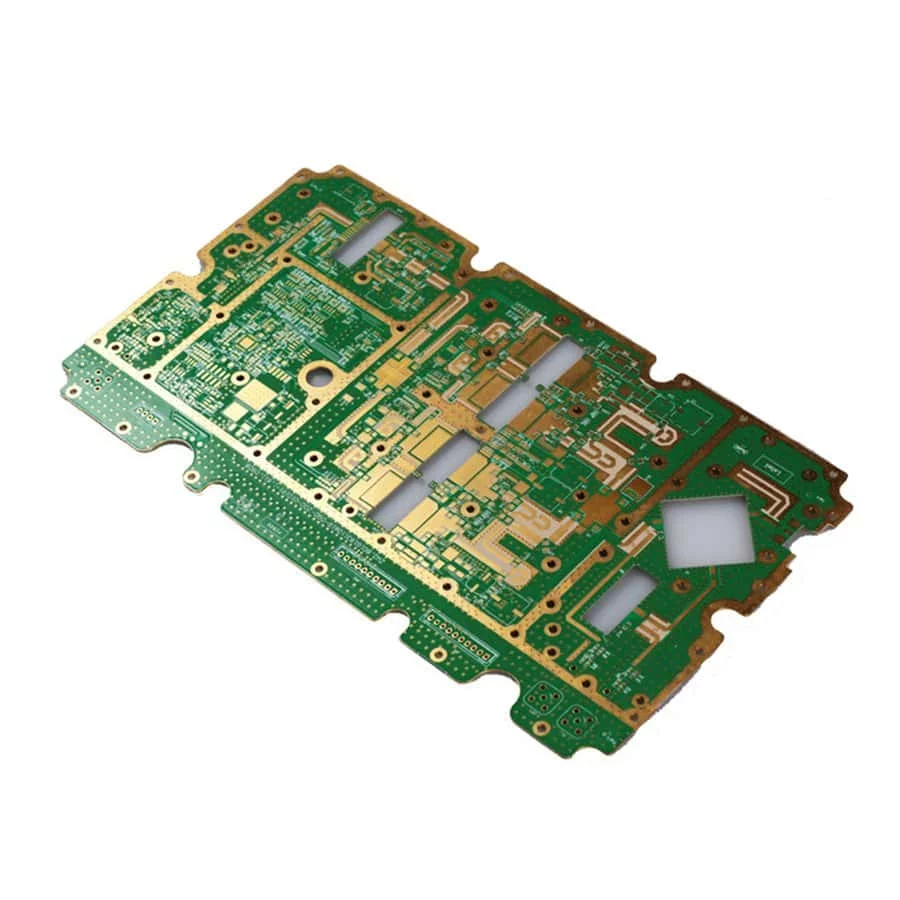

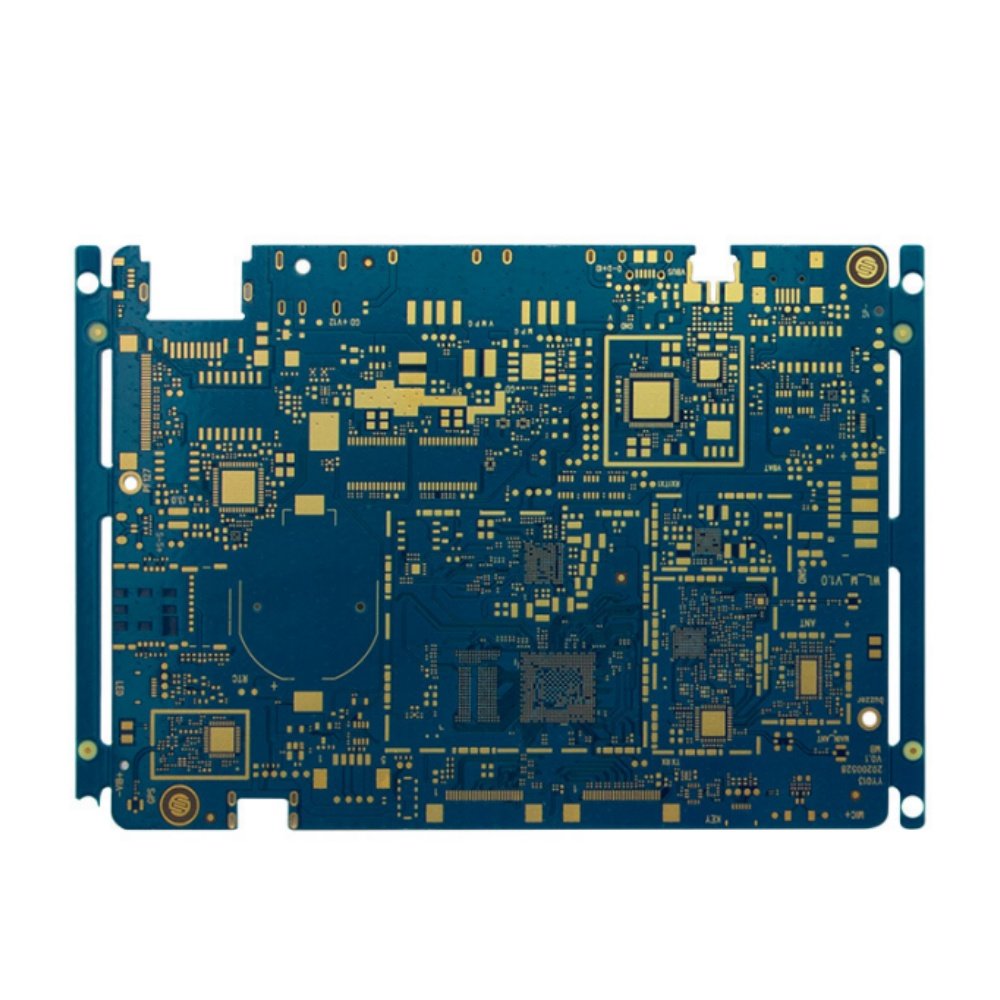

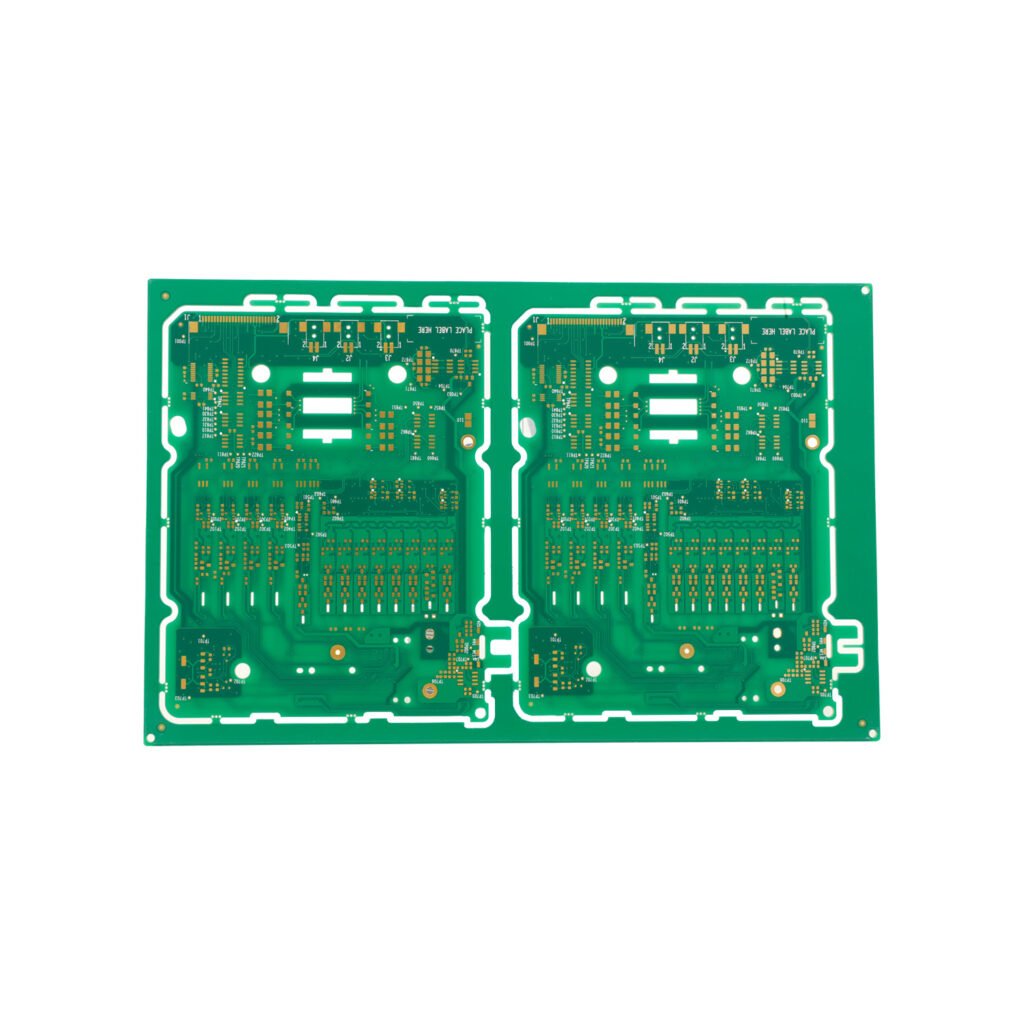

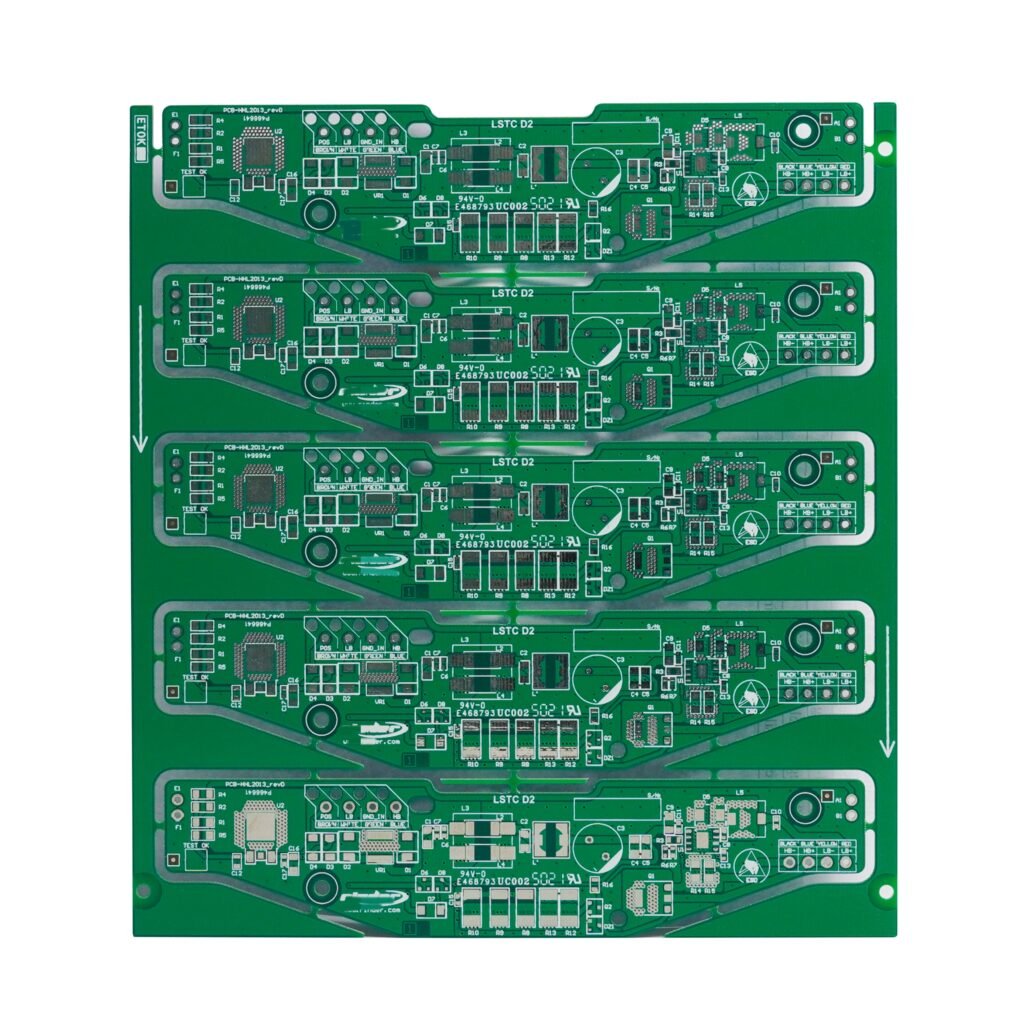

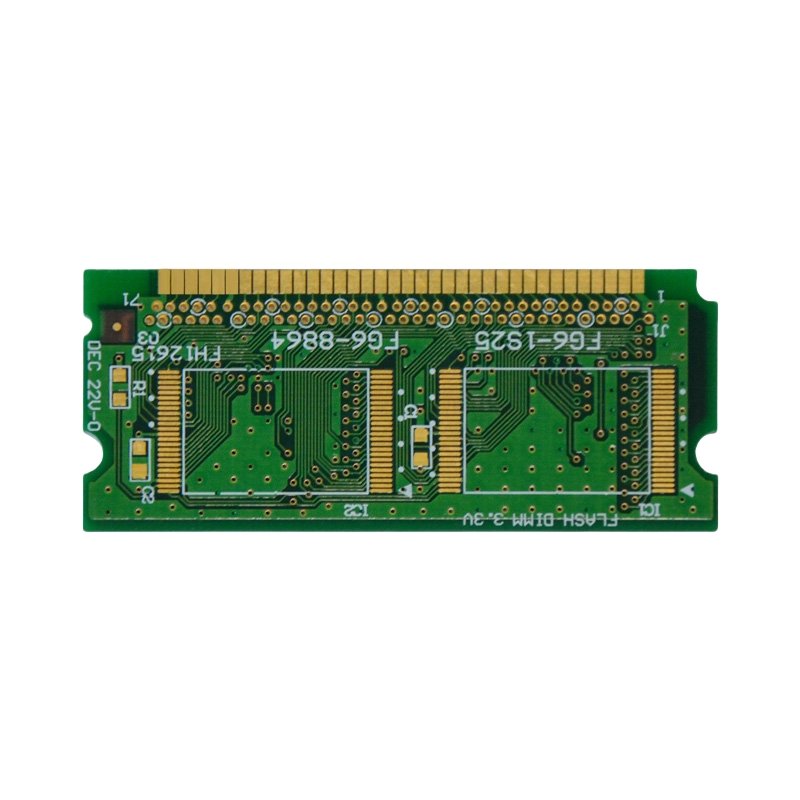

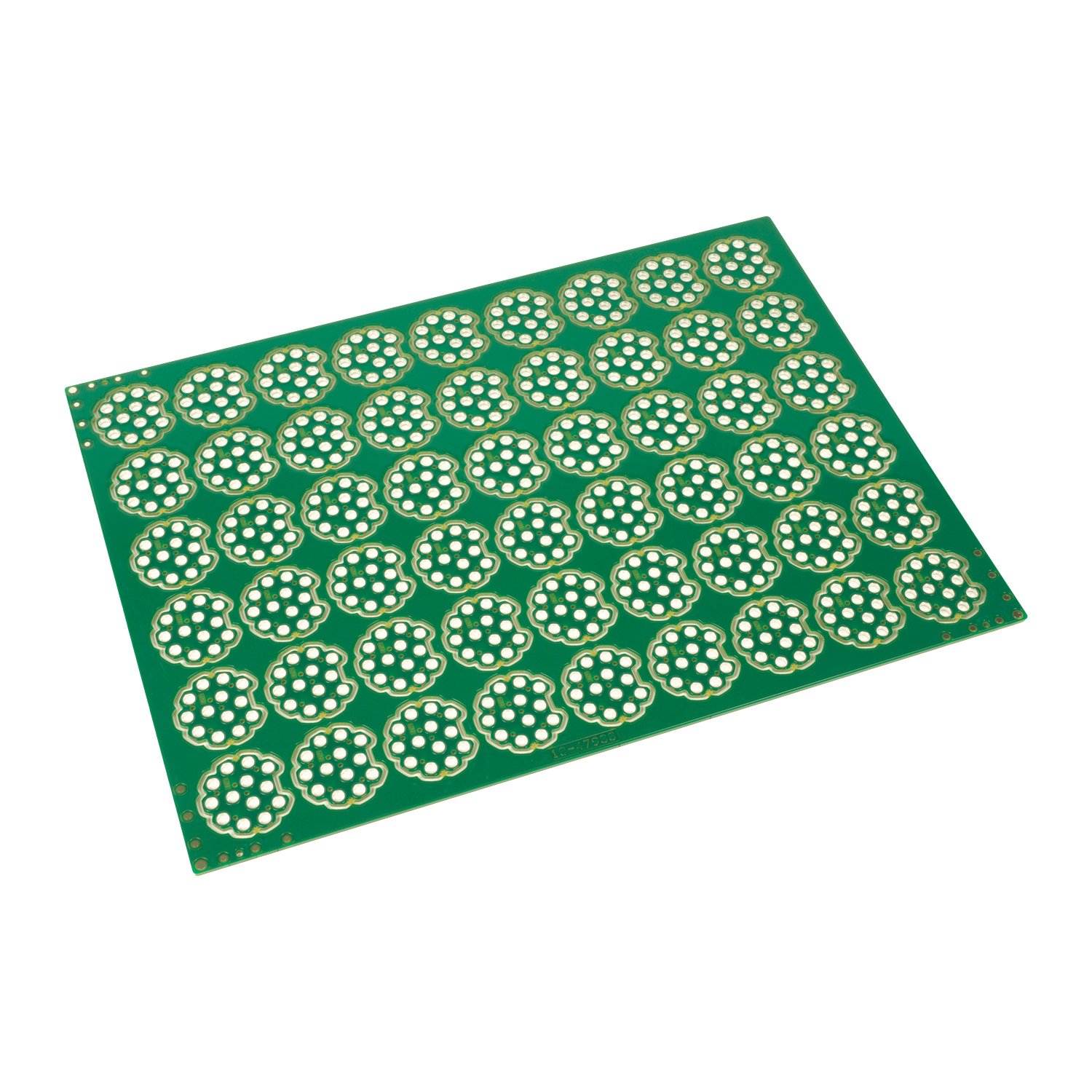

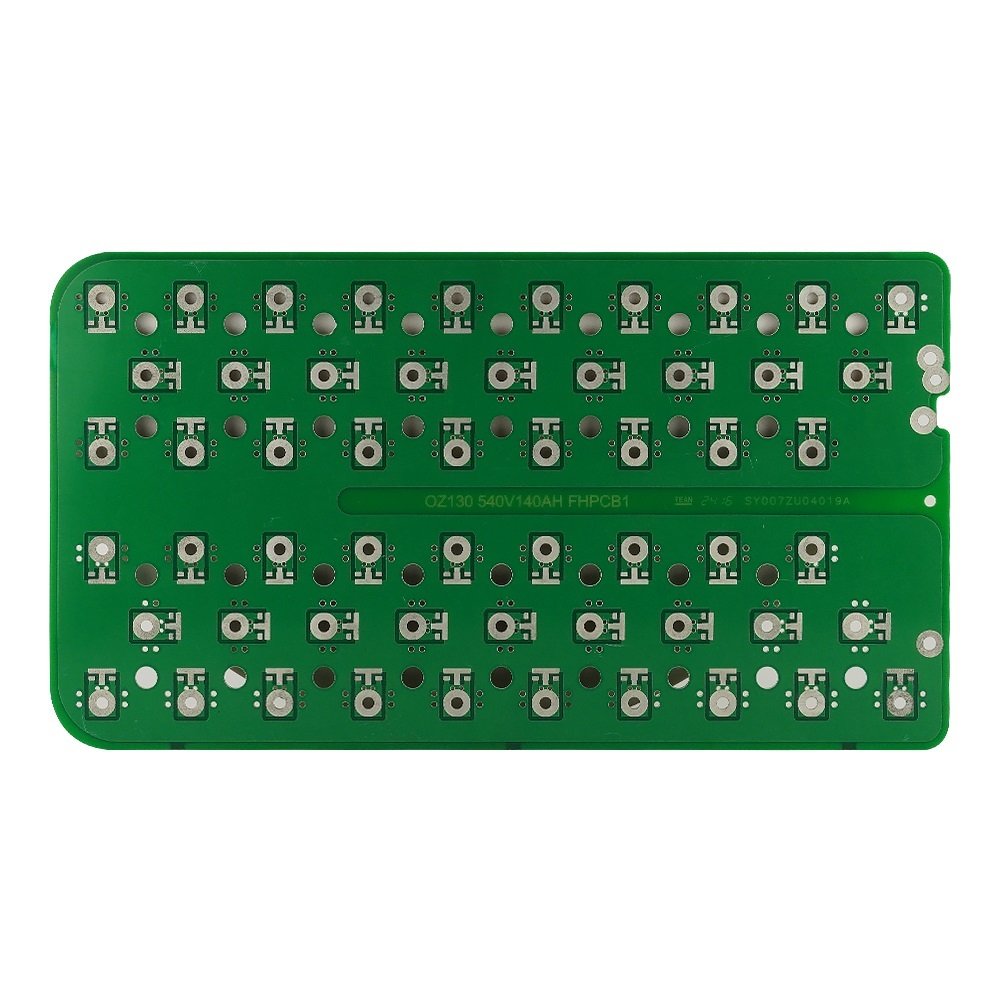

Quick Turn PCB Boards Production

| Layers: | 1-64 L |

| Material: | Fr4 |

| PCB Thickness: | 0.1mm-7mm |

| Cu Thickness: | 0.5-10 OZ |

| Min. Line W/S: | 2mil/2mil |

| Surface Finish: | Immersion Gold |

| Application: | Consumer Electronics/Medical/Industrial/Automotive |

What is quick turn PCB?

Quick turn PCB refers to a printed circuit board (PCB) manufacturing service that completes the production cycle in a short time.

For 1-4 layer fast turn PCB production (complete the whole process from design to finished product) delivery time only 24 hours.

Quick turn PCB is very suitable for small batch and multi-variety production needs, and can respond quickly to market changes. Despite the short production cycle, Ucreate PCB company still maintains high-quality production standards to ensure product reliability and stability.

The production process of quick turn PCB usually includes the following steps:

- Design file review: The manufacturer receives the design files (such as Gerber files and BOM tables) provided by the customer and reviews them to ensure the completeness and accuracy of the files.

- Manufacturability check: Perform DFM (Design for Manufacturability) checks to ensure that the design meets production requirements and reduces potential manufacturing problems. Ucreate team provides free DFM inspection before we start production.

- Material preparation: Prepare the required PCB materials and components according to design requirements.

- Rapid production: Use advanced production technology and equipment such as laser cutting, CNC drilling, etc. for rapid production and assembly.

- Quality inspection: Perform strict quality inspection on the finished product to ensure that the product meets the specification requirements.

- Packaging and shipment: Pack and ship qualified PCB products to customers.

If you have any requirements for PCB/ PCBA/Components, please contact us and we will reply to you as soon as possible!

English

English

中文

中文