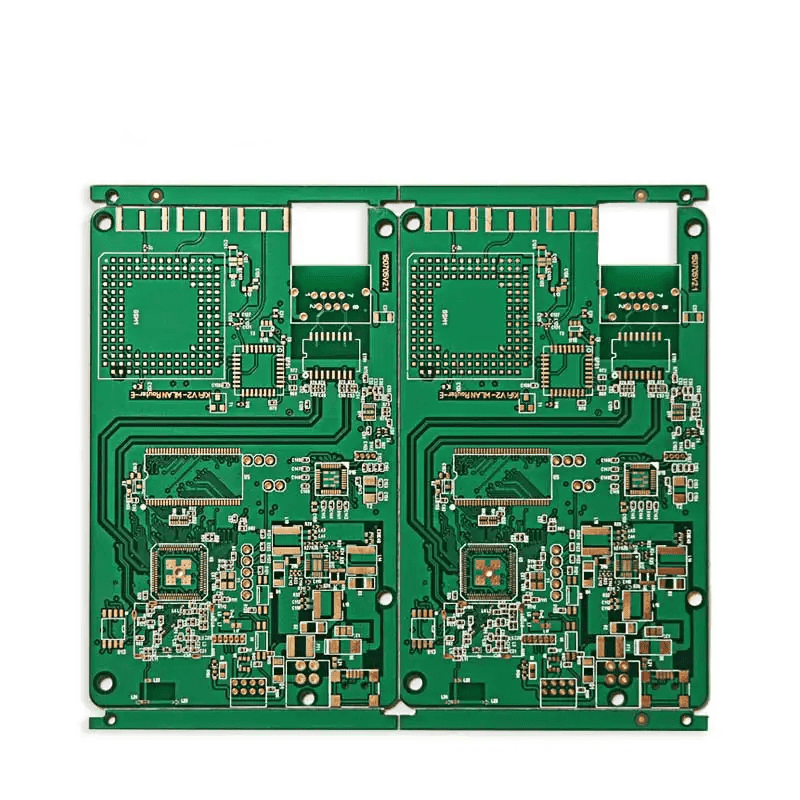

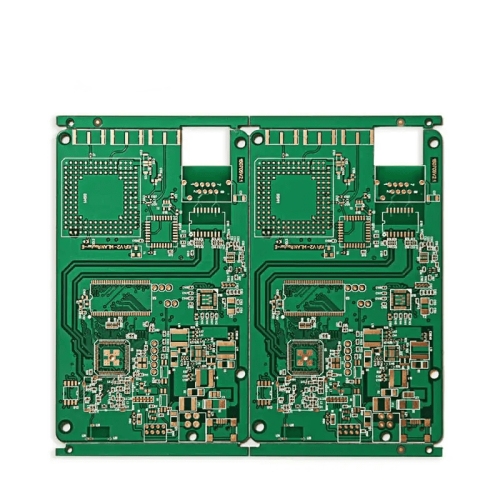

12 Layers Immersion Gold BGA PCB Board

| Layers: | 12 L |

| Material: | Fr-4 |

| PCB Thickness: | 1.6mm |

| Cu Thickness: | 2.0 OZ |

| Min. Line W/S: | 0.075/0.075mm |

| Surface Finish: | Immersion Gold |

| Application: | Medical Electronics |

What is BGA PCB?

BGA stands for “Ball Grid Array,” and PCB stands for “Printed Circuit Board.” A BGA PCB is a type of circuit board that uses ball grid array technology for the attachment of integrated circuits (ICs) and other components.

In a BGA PCB, the ICs are mounted on the surface of the board, and the electrical connections are made by tiny balls of solder that are attached to the bottom of the ICs. These balls are then placed onto a grid of pads on the surface of the PCB, and the solder is melted to create a strong, permanent connection.

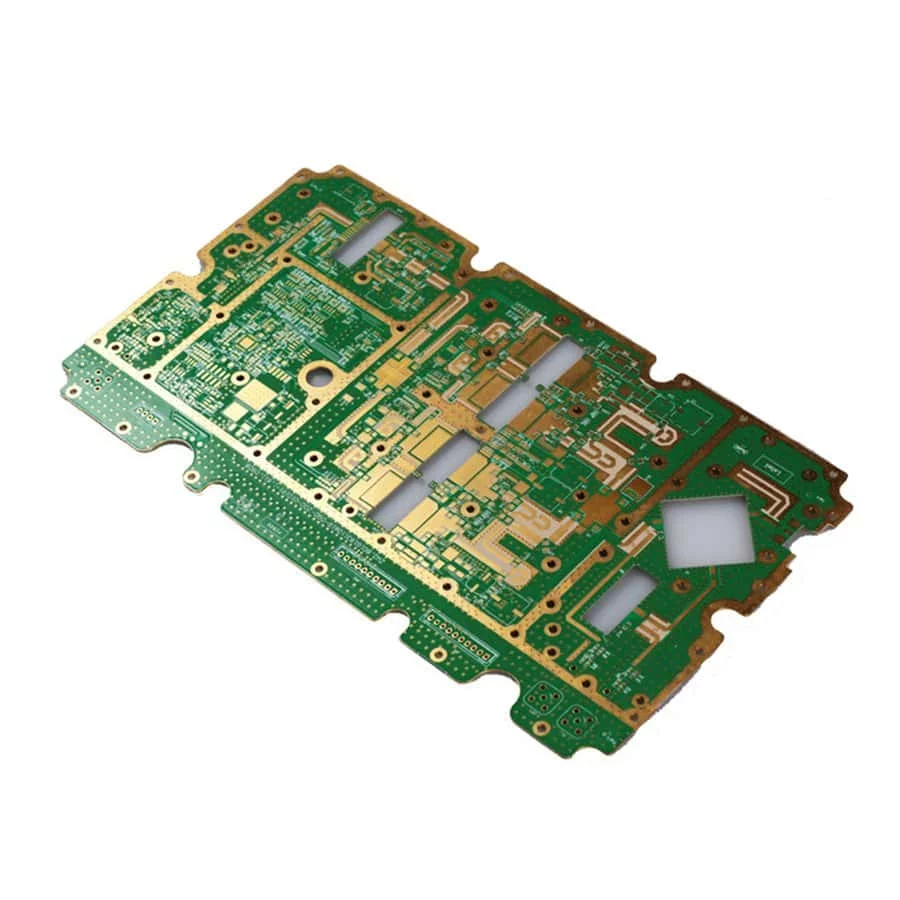

BGA PCBs are commonly used in electronic devices that require high-density circuitry, such as mobile phones, laptops, and other compact electronic devices. The use of BGA technology allows for more efficient use of board space, improved heat dissipation, and higher reliability compared to traditional through-hole or surface-mount component technologies

Advantages:

Small package area and high pin density.

Good high-speed performance, suitable for high-speed signal transmission.

Automated production, improve production efficiency.

Relatively high reliability.

Disadvantages:

The welding process is complicated and requires high-precision control. The reliability after packaging may be affected by external factors such as pressure.

Detection and maintenance are difficult, requiring expensive equipment and technology

BGA PCB, as an advanced integrated circuit packaging technology, has significant advantages in increasing pin density, improving performance, and realizing automated production, but it also has some challenges and problems that need to be solved. With the continuous advancement of technology and the continuous expansion of application scenarios, BGA PCB will play a more important role in the future development of the electronics industry.

If you have any requirements for PCB/ PCBA/Components, please contact us and we will reply to you as soon as possible!

English

English

中文

中文