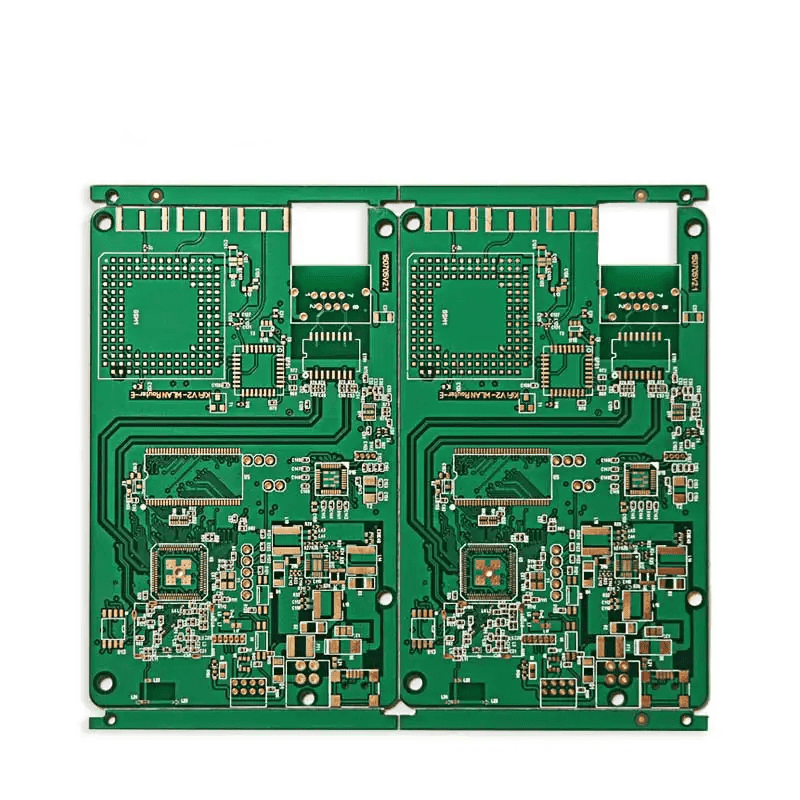

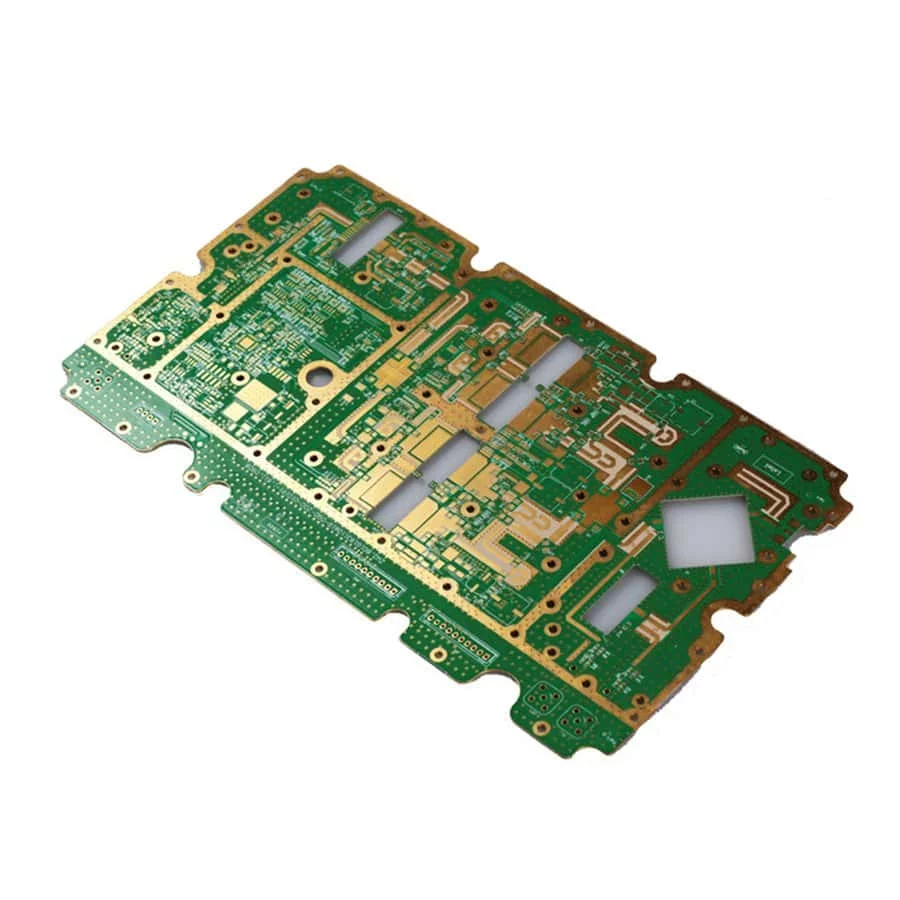

8 Layer BGA PCB Circuit Board

| Layers: | 8 L |

| Material: | FR4 |

| PCB Thickness: | 0.3mm |

| Cu Thickness: | 2.5OZ |

| Min. Line W/S: | 0.15/0.1mm |

| Surface Finish: | Immersion Gold |

| Application: | Consumer Electronics/Medical/Industrial/Automotive |

What is BGA?

BGA, or Ball Grid Array, is a surface mount packaging technology used in integrated circuits. In this packaging, the pins of the integrated circuit are distributed at the bottom of the package in the form of a ball array. These pins correspond to the position of the copper foil on the PCB board during soldering. The solder balls are melted by heating and form a bright contact point under the action of surface tension, thereby achieving the connection between the integrated circuit and the PCB board.

Applications of BGA PCB?

BGA PCB is widely used in various electronic devices, especially those applications that require high-density pins and high-speed performance, such as the packaging of integrated circuits such as microprocessors, graphics processors, and memories. These packaged integrated circuits are connected to other electronic components through BGA PCB, forming the core part of electronic devices.

Features

- High-density pins: BGA packaging can provide more pins than other packaging methods (such as dual in-line package DIP or quad flat package QFP), so that the entire bottom surface of the device can be used as pins, which increases the pin density.

- High performance: Since the pins are distributed over the entire bottom surface and the average wire length is short, the BGA package has better high-speed performance and low inductance characteristics, and is suitable for application scenarios with high requirements for signal transmission speed and quality.

- Automated production: The welding process of BGA packaging requires precise control and is usually completed by automated machines, which improves production efficiency and consistency.

- Reliability: BGA packaging has high reliability, but it may also be affected by external factors such as pressure, leading to reliability problems. In order to improve reliability, technical means such as bottom filling can be adopted

If you have any requirements for PCB/ PCBA/Components, please contact us and we will reply to you as soon as possible!

English

English

中文

中文