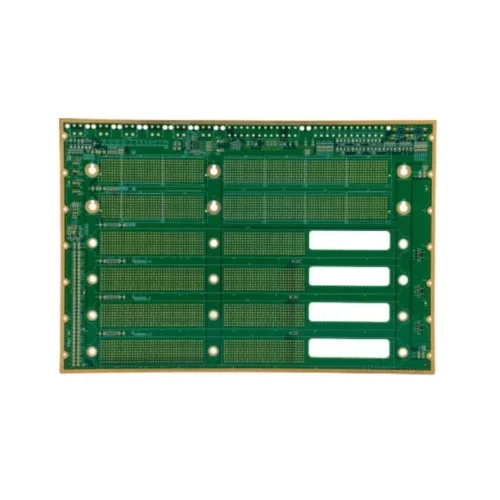

Auto Electronics 4 Layers Immersion Gold PCB

| Layers: | 4 L |

| Material: | Fr-4 |

| PCB Thickness: | 1.2mm |

| Cu Thickness: | 1.5 OZ |

| Min. Line W/S: | 0.1/0.1mm |

| Surface Finish: | Immersion Gold |

| Application: | Auto Electronics |

What is immersion gold PCB?

why use an immersion gold circuit board?

1. Because the crystalline structure formed by immersion gold and gold plating is different, immersion gold will be more golden yellow than gold plating, and customers are more satisfied.

2. Because the crystal structure formed by immersion gold and gold plating is different, immersion gold is easier to weld than gold plating, and will not cause poor welding and cause customer complaints.

3. Because the immersion gold board only has nickel gold on the pad, the signal transmission in the skin effect is on the copper layer and will not affect the signal.

4. Because the crystal structure of immersion gold is denser than that of gold plating, it is not easy to produce oxidation.

5. Because the immersion gold board only has nickel gold on the pad, it will not produce gold wires and cause micro shorts.

6. Because the immersion gold board only has nickel gold on the pad, the combination of the solder mask on the circuit and the copper layer is stronger.

7. The project will not affect the spacing when making compensation.

8. Because the crystal structure formed by immersion gold and gold plating is different, the stress of the immersion gold plate is easier to control, and for products with bonding, it is more conducive to bonding processing. At the same time, because immersion gold is softer than gold plating, the immersion gold plate is not wear-resistant as a gold finger

9. The flatness and standby life of the immersion gold plate are as good as those of the gold-plated plate.

If you have any requirements for PCB/ PCBA/Components, please contact us and we will reply to you as soon as possible!

English

English

中文

中文