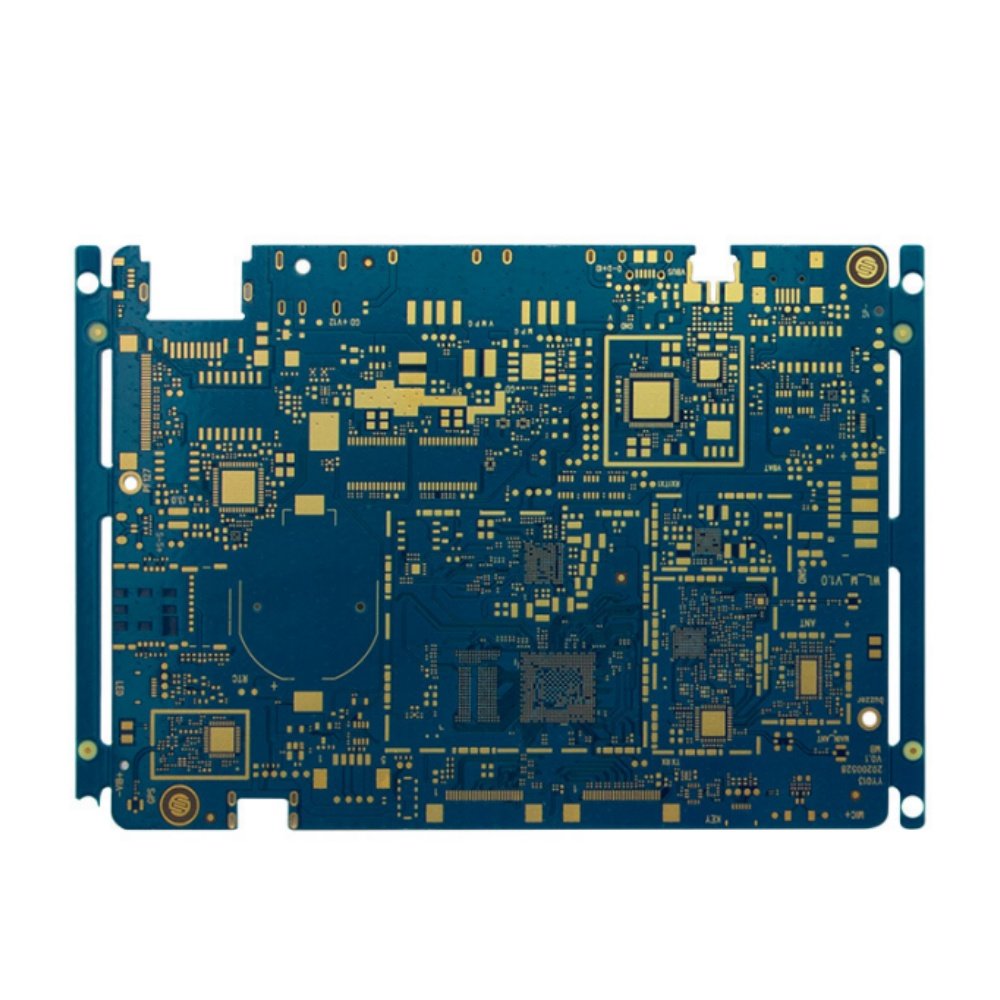

Security Electronics Multilayer Layer 2+6+2 HDI PCB

| Layers: | 10 L |

| Material: | Fr-4 |

| PCB Thickness: | 1.5mm |

| Cu Thickness: | 1.0 OZ |

| Min. Line W/S: | 0.075/0.075mm |

| Surface Finish: | Immersion Gold |

| Application: | Security Electronics |

What is a high-density interconnect (HDl) PCB circuit board?

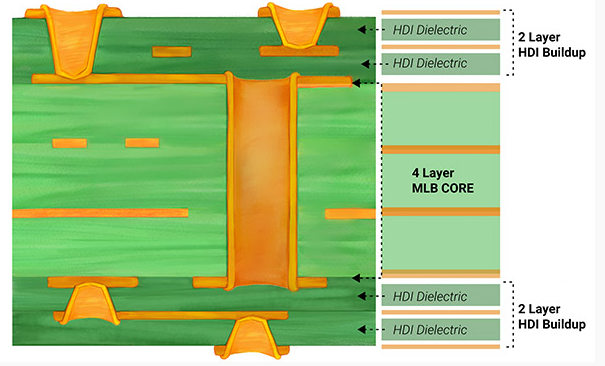

High Density Interconnect (HDI) PCB circuit board is a circuit board with relatively high line distribution density using microblind and buried via technology. The most effective way to increase board density is to reduce the number of vias and precisely place blind and buried vias to meet this requirement, resulting in an HDI board.

This is a process that includes wires on the inner layer and wires on the outer layer, and then uses holes and metallization in the holes to achieve the function of bonding between the inner layers of each layer. HDI PCB is a printed circuit board with a higher wiring density per unit surface areathan a standard PCB board. HDI PCB uses some or all of the following features to reduce the size of the PCB:

1. Line and space less than or equal to 100 microns.

2. Via hole less than or equal to 150 microns.

3. Capture pads are less than or equal to 400 microns.

4. The capture pad density exceeds 20 pads per square centimeter.

Increased interconnect density enhances signal strength and increases reliability. In addition, HDI PCB makes it possible to manufacture smaller and more powerful electronic devices thanks to design efficiency and space maximization.

If you have any requirements for PCB/ PCBA/Components, please contact us and we will reply to you as soon as possible!

English

English

中文

中文