In PCBA (printed circuit board assembly) manufacturing, tin penetration (i.e., the degree to which solder fills the through-holes in the PCB or the pin holes of components) is one of the key indicators for measuring soldering quality. Insufficient solder penetration can lead to cold solder joints, poor electrical connections, or even product failure, while excessive solder penetration may cause solder overflow and contaminate adjacent solder joints. Welding methods, as core process parameters influencing solder penetration, directly determine the final soldering outcome through mechanisms such as thermal conductivity efficiency and solder flow characteristics.

I. The core significance and evaluation criteria of tin penetration rate

The tin penetration rate generally refers to the percentage of the vertical filling height of the solder in the through hole relative to the hole depth. Industry requirements are generally as follows:

- Conventional through-hole solder joints: Tin penetration rate ≥ 75% (≥ 90% required in some high-reliability scenarios);

- Critical signal holes (such as power/ground): The higher the tin penetration rate, the better (close to 100% to reduce contact resistance).

When the tin penetration rate is insufficient, the contact area between the solder and the pin is reduced, which can easily lead to “cold solder joints” (electrical breaks). If the tin penetration rate is too high, solder may overflow onto adjacent pads, leading to the risk of short circuits.

II. Mainstream welding methods and their impact on tin penetration rates

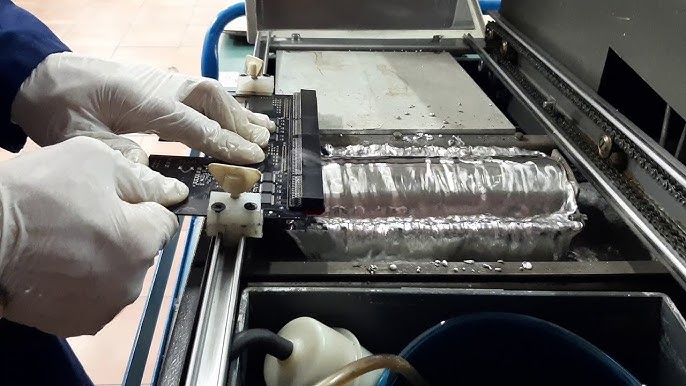

1. Wave soldering — Traditional, efficient, but dependent on process control

Principle: Melted solder (usually Sn63/Pb37 or lead-free alloy) is formed into a “wave peak” by a pump. The PCBA passes through the wave peak at a certain angle (usually 3° to 7°), and the solder fills the through-holes under the combined action of capillary action and gravity.

Impact on tin penetration rate:

- Advantages: Suitable for batch through-hole soldering, strong solder flow dynamics (wave impact force can reach 5~1N), if parameters are properly matched (such as temperature 245~260℃, speed 1.2~1.5m/min), solder penetration rate can reach 85%~95%.

- Disadvantages: The tin penetration rate is significantly affected by PCB design (such as hole diameter/pad ratio, copper thickness), flux activity, wave height, etc. Common issues:

- If preheating is insufficient (PCB base temperature < 100°C), solder fluidity will be poor and solder penetration may drop below 60%.

- When the aperture is too small (e.g. <8 mm) or the pad spacing is too close, uneven solder penetration may occur due to solder bridging.

- Oxidation of component pins or excessive flux residue hinders solder penetration.

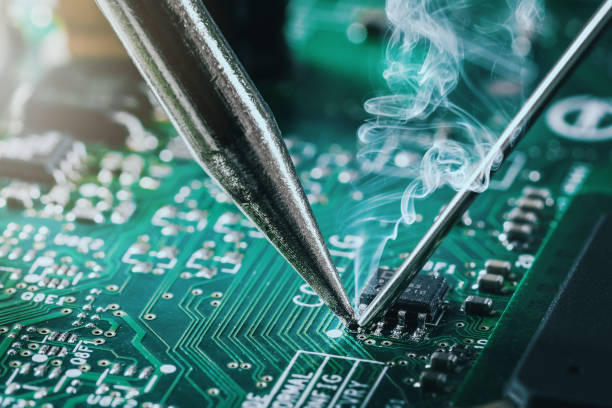

2. Manual Soldering — Flexible but inconsistent

Principle: The operator heats the solder pad and lead with an electric soldering iron (usually at a temperature of 300-350°C) while adding solder wire to supplement the solder. Capillary action is used to fill the through-hole with solder.

Impact on tin penetration rate:

- Advantages: Suitable for small batch repairs or irregular component welding, with high flexibility.

- Disadvantages: Tin penetration rate is highly dependent on operational skills — if the soldering iron temperature is insufficient (<300°C), heating time is too short (<2 seconds), or solder quantity is insufficient, the solder will only adhere to the hole opening, resulting in a tin penetration rate of only 50%–70%; Conversely, if the temperature is too high (>380℃), it may cause delamination of the PCB substrate or solder oxidation.

Typical problem: When beginners weld, they often encounter the phenomenon of “tin accumulation at the hole opening but hollow inside” (tin penetration rate < 60%), while skilled engineers can stabilise the tin penetration rate at 80% to 90% by using the technique of “heating the pin first and then applying the solder“.

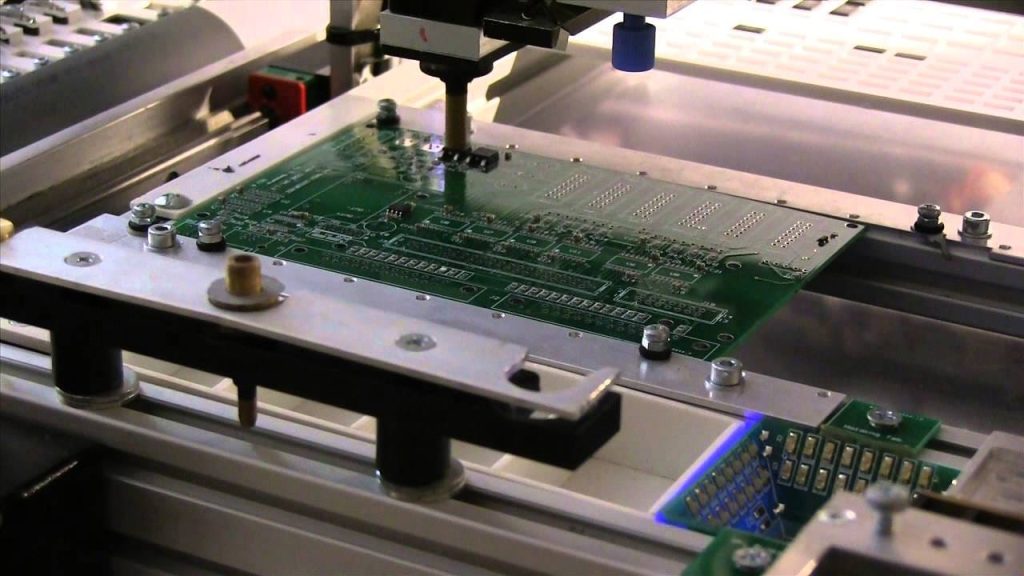

3. Reflow Soldering — Suitable for surface mounting (SMT), through holes require special design

Principle: By heating the solder paste (containing solder powder and flux), the solder is melted, and surface tension is used to achieve self-positioning of the solder. Traditional reflow soldering is primarily used for SMT surface-mount components (such as chips and resistors), but for through-hole components (THD), the “through-hole reflow” (Pin-in-Paste, PIP) process must be used—that is, additional solder paste is printed on the through-hole pads, and during reflow, the melted solder flows downward to fill the holes.

Impact on tin penetration rate:

- Advantages: Suitable for high-density circuit boards (such as mobile phone motherboards), with high welding consistency (temperature curve controllable).

- Disadvantages: Tin penetration rates are typically lower than those achieved with wave soldering—due to limited solder paste volume (which must also accommodate adjacent surface-mount components)—and the “top-down” melting mode of reflow soldering relies on capillary action, resulting in weaker filling dynamics. The solder penetration rate for conventional through-hole reflow is only 60%–80%, and may be even lower if the hole diameter is >0 mm or the pad area is small.

Optimisation direction: By increasing the amount of solder paste on the through-hole pads (e.g. the steel mesh aperture is 10% to 20% larger than the through-hole diameter) and extending the reflow time (maintaining a peak temperature of 245°C for 60 to 90 seconds), the tin penetration rate can be increased to over 80%.

III. Other influencing factors and comprehensive optimisation recommendations

In addition to the welding method itself, the following factors also significantly affect tin penetration:

- PCB design: Matching of via diameter and pin diameter (recommended gap of 2–0.4 mm), pad ring width (≥0.3 mm), copper thickness (1–2 oz is recommended; excessive thickness reduces thermal conductivity efficiency);

- Flux: Insufficient activity (such as rosin-based flux) may result in the inability to remove the oxide film, hindering solder penetration.

- Component pins: Plating quality (e.g., tin plating thickness < 1 μm is prone to oxidation), degree of pin oxidation (newly unsealed components have higher tin penetration).

Comprehensive optimisation strategy:

- Wave soldering is the preferred choice for mass production (high and stable tin penetration rate), combined with nitrogen protection (to reduce oxidation) and appropriate wave parameters.

- High-density board cartoon hole components use through-hole reflow process, but solder paste quantity needs to be optimised through steel mesh design.

- Repair or small batch scenarios, when choosing manual soldering, operators must be strictly trained (such as “three temperature controls”: preheating temperature, soldering iron temperature, soldering time).

Conclusion

Welding methods are the core control variables for PCBA solder penetration rate. Wave soldering, with its high fluidity, is suitable for high solder penetration requirements. Reflow soldering can balance density and reliability through process optimisation, while manual soldering relies on operational precision. Understanding the fundamental differences between various soldering methods and comprehensively adjusting parameters such as PCB design and material selection are essential to achieving the soldering objective of “high solder penetration rate + low defect rate,” thereby laying the foundation for the long-term stable operation of electronic products.

English

English

中文

中文