Gerber files are a standardized PCB design output format that accurately records every layer of the board: trace routing, pad locations, via sizes, solder mask, silkscreen, and more.

The precision of this vector format (down to the micron level) ensures manufacturers can fully reproduce design details, avoiding manufacturing errors caused by data ambiguity. Manufacturing facilities use this data to transform designs into physical circuit boards.

The Gerber file is the PCB industry’s equivalent of this blueprint set.

The Gerber file is the PCB industry’s equivalent of this blueprint set.

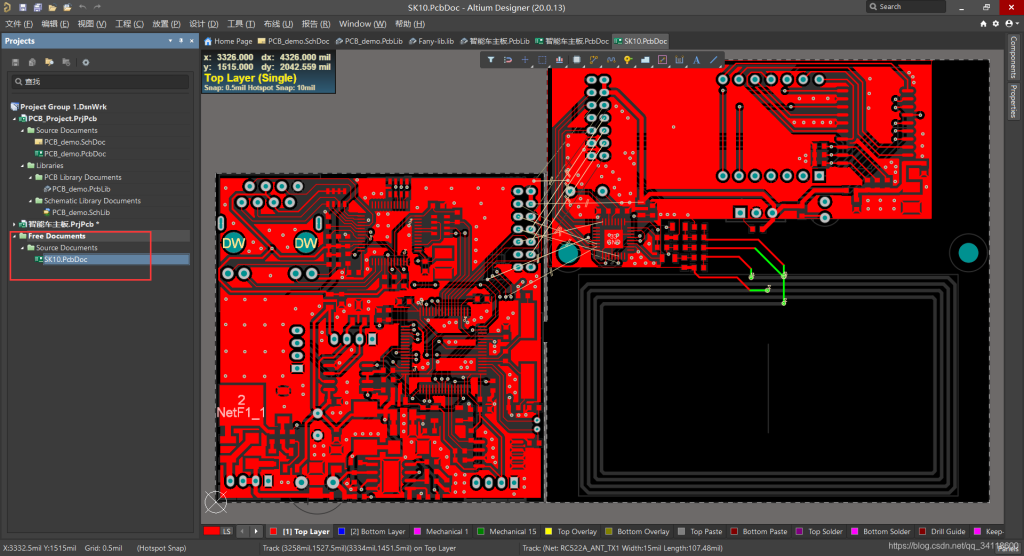

When a design engineer completes a board layout using software like Altium Designer, KiCad, or OrCAD, they are working in a proprietary, information-rich environment. This file contains the schematic, the board layout, component libraries, design rules, and even 3D models. It is a comprehensive project file, but it is not directly usable by the manufacturer. The manufacturer doesn’t need to know the designer’s thought process or the specific tools they used; they need clear, standardized instructions on what to physically create.

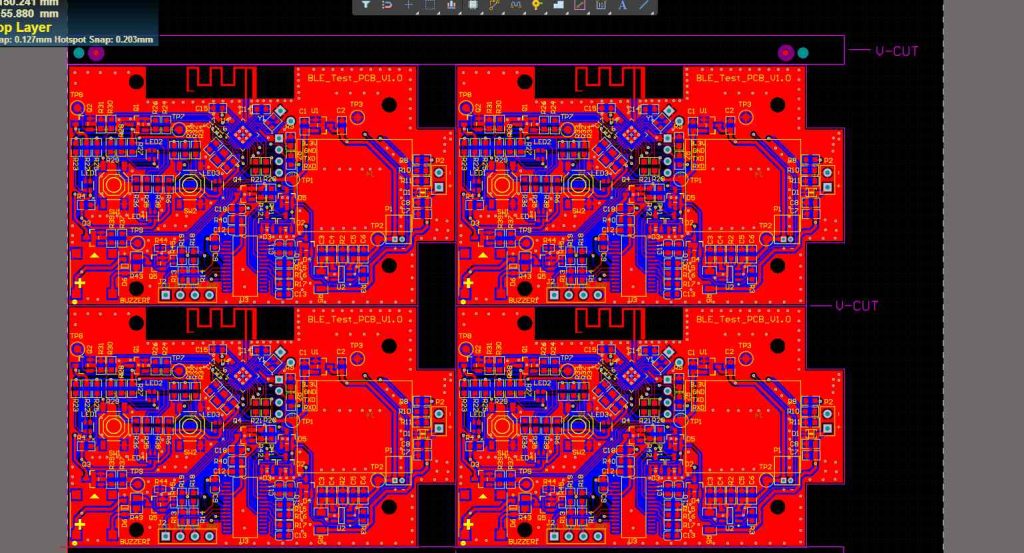

This is where the Gerber format, officially known as RS-274X, comes in. The process of generating Gerbers, often called “plotting,” is the act of translating the complex design into a series of simple, layered images. Each image represents a distinct physical layer of the PCB:

Copper Layers: A separate Gerber file is generated for each signal layer (Top, Mid-1, Mid-2, Bottom, etc.).

- Solder Mask: A file defining where the green (or other colored) protective coating should be removedto expose the copper pads for soldering.

- Silkscreen: The file for the white (or other colored) legend printed on the board, showing component outlines, reference designators, and logos.

- Solder Paste: A critical file for assembly, indicating where solder paste should be applied to surface-mount pads before components are placed.

- Drill Drawing: While often handled by a separate Excellon drill file, the drill data is an integral part of the Gerber dataset, specifying the location and size of every hole to be drilled.

Importance of Gerber files in PCB manufacturing:

1. Carrying Core Manufacturing Data

Gerber files are the industry’s lingua franca, whether for domestic or international PCB/PCBA factories. While the original files generated by different design software may differ, once converted to Gerber, the factory can seamlessly interpret and process them.

PCBA manufacturing requires micron-level precision. Gerber files provide precise information such as trace width and spacing, eliminating production deviations caused by miscommunication.

From circuit board manufacturing to placement, soldering, and final functional testing, every step is essential. Gerber files not only guide the board fabrication process but also help the SMT workshop accurately locate component pads.

2. Guarantee of quality and cost

The integrity of Gerber files directly determines PCBA quality. Missing layers, incorrect labeling, or insufficient internal clearance can lead to defects such as routing errors and pad failures. Manufacturers also use Gerber data, such as layer counts and drilling data, to accurately calculate material costs and processing time, optimizing resource allocation. For example, accurate solder mask information can prevent solder shorts, while clear silkscreen labeling can reduce component placement errors.

3. Security

Compared to directly providing the original design files, Gerber only contains the information necessary for manufacturing, which not only meets production needs but also protects the core design from being leaked.

Summary

Gerber files are not only the “passport” for PCBA processing but also the digital link for the electronics manufacturing ecosystem.

From design verification to mass production, their standardization, accuracy, and compatibility ensure efficient collaboration across the entire supply chain.

For businesses, preparing a standard, complete Gerber file not only shortens delivery times but also avoids losses caused by rework.

In China, the PCB engineers of UCREATE (800 staff, 120,000 m², 100 % renewable electricity, ISO9001, ISO14001,ISO 13485 + IATF 16949 + UL), have more than 10 years experience in PCB industry,send us your Gerber file to get free DFM check. EMAIL: sales@ucpcba.com

English

English

中文

中文