Aluminium substrate is a metal-based copper-clad laminate with good heat dissipation and usually consists of a three-layer structure: a circuit layer (copper foil), an insulating layer and a metal base layer. This material is commonly used in LED lighting products and, due to its excellent heat dissipation properties, is widely used in electronic devices that require efficient heat dissipation. The front side of an aluminium substrate is usually white and is used for soldering LED pins, while the reverse side, which is the natural colour of aluminium, is usually coated with a thermally conductive gel paste to enhance thermal conductivity. Aluminium substrates are not only suitable for LED lamps and lanterns, but are also widely used in audio equipment, power supply equipment, automobiles and other fields, showing their versatility and importance in electronic engineering.

The special structure of aluminium substrate makes it outstanding in heat dissipation performance. Its circuit layer consists of copper foil, which provides good electrical conductivity; the insulating layer is made of low thermal resistance thermally conductive insulating material, which ensures the safety and stability of the circuit; and the metal base layer is usually aluminium or copper, which further enhances the heat dissipation effect. This design allows aluminium substrates to eliminate the need for additional heat sinks in the surface mount (SMT) process for power components, greatly reducing the size of the device while maintaining good heat dissipation.

In addition, aluminium substrate not only has good heat dissipation performance, but also has excellent insulation and mechanical properties, which makes it an ideal choice in a variety of electronic devices. For example, in LED lighting products, aluminium substrates are able to conduct heat quickly, effectively lowering the operating temperature of LED lights and extending their service life.

Features of aluminum substrate:

- Adopt surface mount technology (SMT);

- Effectively handle heat diffusion in circuit design;

- Reduce product operating temperature, improve product power density and reliability, and extend product life;

- Reduce product size, reduce hardware and assembly costs;

- Replace fragile ceramic substrates to achieve better mechanical durability.

The structure of PCB aluminum:

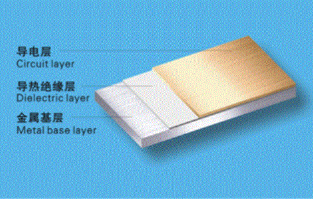

PCB aluminum-based copper-clad laminate is a metal circuit board material, composed of copper, thermal insulation layer and gold substrate. Its structure is divided into three layers:

Cireuitl Layer: Equivalent to the copper-clad laminate of ordinary PCB, the circuit copper thickness is 1 OZ to 10 OZ.

Dieicctic Layer: The insulation layer is a layer of low thermal resistance thermal conductivity: insulation material. The thickness is: 0.003″ to 0.006″ inches. It is the core technology of aluminum-based copper-clad laminate and has been UL certified.

Base Layer: It is a gold-clad substrate, generally aluminum or optional copper. Aluminum-based copper plate and traditional epoxy glass cloth laminate, etc.

As shown in the figure above, the PCB aluminum substrate consists of a circuit layer, a thermal insulation layer and a metal base layer. The circuit layer (i.e., copper foil) is usually etched to form a printed circuit so that the various components of the assembly are interconnected. In general, the circuit layer requires a large current carrying capacity, so a thicker copper foil should be used, with a thickness of 35um~280um; the thermal insulation layer is the core technology of the PCB aluminum substrate. It is generally composed of a special polymer filled with special ceramics, with low thermal conductivity, excellent viscoelastic properties, and the ability to resist thermal aging and withstand mechanical and thermal stress. The thermal insulation layer of high-performance PCB aluminum substrates such as IMS-H01, IMS-HO2 and LED-0601 uses this technology, which makes it have extremely excellent thermal conductivity and high-strength electrical insulation performance; the metal base layer is the supporting component of the aluminum substrate, which requires high thermal conductivity. It is generally an aluminum plate, and a copper plate can also be used (copper plates can provide better thermal conductivity), which is suitable for conventional mechanical processing such as drilling, punching and cutting.

PCB materials have incomparable advantages over other materials. Suitable for surface mounting SMT technology of power components. No need for heat sink, greatly reduced size, excellent heat dissipation effect, good insulation performance and mechanical properties.

PCB aluminum substrate uses:

Uses: power hybrid IC (HIC).

- Audio equipment: input and output amplifiers, balanced amplifiers, audio amplifiers, preamplifiers, power amplifiers, etc.

- Power supply equipment: switching regulators, DC/AC converters, SW regulators, etc.

- Communication electronic equipment: high-frequency amplifiers, filter appliances, and transmission circuits.

- Office automation equipment: motor drivers, etc.

- Automobiles: electronic regulators, igniters, power controllers, etc.

- Computers: CPU boards, floppy disk drives, power supply devices, etc.

- Power modules: inverters, solid-state relays, rectifier bridges, etc.

English

English

中文

中文