OSP (Organic Solderability Preservative) is the chemical growth of an organic copper complex compound on the surface of copper. This organic film protects the clean bare copper on the circuit board from rusting (sulphurisation or oxidation) in a normal storage environment, and can be easily removed by fluxes and dilute acids during the circuit board assembly process to reveal clean copper surfaces for soldering with molten solder.

This OSP is basically a transparent protective film, generally with the naked eye is extremely difficult to detect its existence, the connoisseur can be refracted through the reflection to see whether there is a layer of transparent film on the copper foil to determine, but also because of the OSP boards and general bare copper boards do not look too different, which also causes the board factory in the value of the inspection and measurement of the difficulty.

Organic copper protectant (OSP) if there is a hole just in the copper surface, the copper surface will be oxidised from the hole, which in turn affects the poor SMT assembly, and the thicker the thickness of the organic copper protectant, the better the protection of the copper foil, but also need a relatively strong active flux to clear it for soldering, so the general requirements of the OSP into the thickness of the film between 0.2-0.5um.

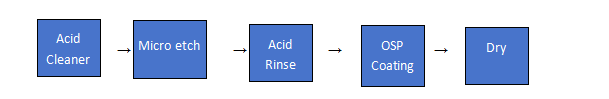

OSP (Organic Solder Preservative) Production Flow Chart

Acid Cleaner

The main purpose is to remove oxides, fingerprints, grease and other contaminants that may have appeared on the copper surface during the pre-production process, in order to obtain a clean copper surface.

Micro-etch:

The main purpose of micro-etch is to remove the more serious oxides on the copper surface and produce a uniform and bright copper surface with micro-roughness, so that the subsequent OSP film can be attached and more fine and uniform. Generally, there is a positive correlation between the luster and colour of the copper surface after OSP film formation and the selected micro-etch solution, because different solutions will cause different roughness of the copper surface, and the roughness will affect the refractive index and angle of light.

Acid Rinse:

The function of acid rinse is to thoroughly remove the residual material on the copper surface after micro-etching to ensure a clean surface for the next process.

OSP Coating:

A layer of organic copper mismatched film is grown on the copper surface to protect the copper surface from oxidation during storage in contact with the atmosphere. Generally, the thickness of OSP film is 0.2-0.5um.

Influence OSP film elements are:

- PH value of OSP bath

- Concentration of OSP bath

- Total acidity of OSP bath

- Operating temperature

- Response time

The water washing after OSP should be strictly controlled at pH2.1 or above to avoid over-acidic water washing to etch and dissolve the OSP film, resulting in insufficient thickness.

Dry:

To ensure that the coating layer on the surface of the board and inside the holes is dry, it is recommended to use hot air at 60-90°C for 30 seconds. (This temperature and time may vary depending on the OSP material).

Advantages and disadvantages of the OSP process

Advantage:

Environmentally friendly: the use of water-based organics is more environmentally friendly and low energy consumption.

Low cost: low amount of soaking material and detergent.

Good surface finish: smooth surface after treatment.

Simple and repairable process: easy to repair and suitable for mass production.

Disadvantages:

Environmental issues: water-based organics use special solvents and form waste water.

Temperature sensitivity: with the change of time and temperature increase, the aging phenomenon is obvious.

Short shelf life: coatings have a short shelf life after opening.

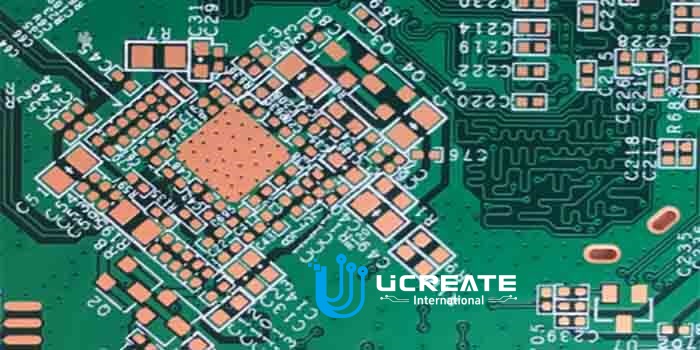

The Surface finishing Ucreate can off : HASL(with Pb free), Plated Ni/Au, ENIG, Immersion Tin, Immersion Ag, OSP,etc. We have more than 20+ years experience in manufacturing PCB, we can produce 1-68 layers printed circuit board, share with us any specail requirement you need. Ucraete team will offer you best solution. Send your Gerber file for free DFM check. Our offical email: sales@ucpcba.com

English

English

中文

中文