In the fast-paced world of electronics manufacturing, the success of a product often hinges on the quality and reliability of its printed circuit board (PCB). As the backbone of virtually all electronic devices, PCBs must not only meet functional requirements but also be optimized for efficient and cost-effective production. This is where Design for Manufacturability (DFM) becomes critical. At Ucreate, we leverage our deep engineering expertise, advanced manufacturing capabilities, and customer-centric approach to deliver PCB solutions that are not only innovative but also manufacturable at scale.

What is PCB DFM?

Design for Manufacturability (DFM) is a proactive engineering approach that involves designing PCB layouts in a way that simplifies manufacturing, reduces costs, and improves product quality. A thorough DFM check identifies potential manufacturing issues early in the design phase, minimizing the risk of costly redesigns, production delays, and quality defects.

DFM for PCBs encompasses a wide range of considerations, including material selection, component placement, trace routing, via design, solder mask application, and adherence to industry standards. The goal is to ensure that the PCB can be manufactured efficiently using standard processes and equipment, without compromising performance or reliability.

The Importance of DFM in PCB Manufacturing

Without a robust DFM process, even the most innovative PCB designs can encounter significant challenges during production. Common issues include:

Component placement conflicts: Overlapping or improperly spaced components can lead to assembly errors or soldering defects.

Insufficient clearances: Inadequate spacing between traces, pads, or vias can cause short circuits or electrical failures.

Unrealistic tolerances: Tight tolerances may be difficult to achieve with standard fabrication methods, leading to yield loss.

Thermal management issues: Poor thermal design can result in overheating, reducing the lifespan and reliability of the product.

Incompatibility with automated assembly: Designs that do not consider pick-and-place or reflow soldering processes can slow down production and increase labor costs.

By integrating DFM checks into the design workflow, these issues can be identified and resolved before the design is finalized, ensuring a smoother transition from prototype to production.

Our DFM Expertise: A Competitive Advantage

At Ucreate, we understand that successful PCB manufacturing begins with intelligent design. Our comprehensive DFM check process is a cornerstone of our commitment to quality, efficiency, and customer satisfaction. Here’s how our capabilities set us apart:

1. Experienced Engineering Team

Our team of PCB design and manufacturing engineers brings decades of combined experience across a wide range of industries, including telecommunications, automotive, medical devices, aerospace, and consumer electronics. This cross-disciplinary expertise allows us to anticipate and address manufacturability challenges specific to each application.

Our engineers work closely with customers during the design phase, offering actionable feedback and recommendations to optimize layouts for manufacturability. Whether it’s adjusting trace widths, relocating vias, or suggesting alternative components, we ensure that every design is production-ready.

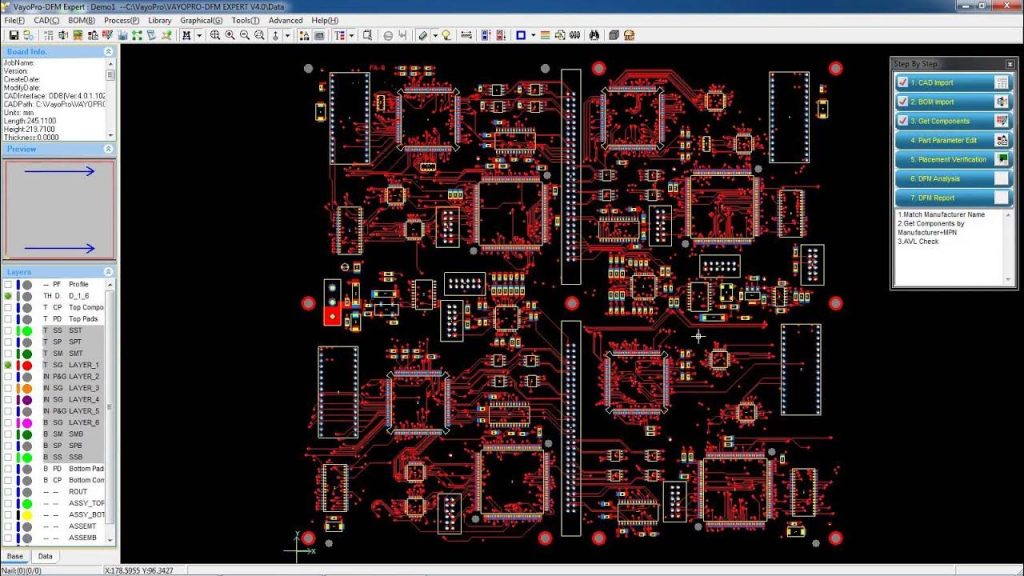

2. Advanced DFM Tools and Software

We utilize industry-leading DFM analysis software that performs automated checks against a comprehensive set of design rules. These tools evaluate aspects such as:

- Minimum trace and space widths

- Drill hole sizes and aspect ratios

- Annular ring specifications

- Solder mask and silkscreen clearances

- Copper balance and thermal relief

- Impedance control and signal integrity

By leveraging these tools, we can quickly identify potential issues and provide detailed reports to our customers, enabling informed design decisions.

3. State-of-the-Art Manufacturing Facilities

Our manufacturing capabilities are a key enabler of effective DFM implementation. With advanced PCB fabrication and assembly lines, we maintain tight process controls and high yield rates. Our facilities are equipped with:

- High-precision CNC drilling and routing machines

- Laser direct imaging (LDI) for fine-line etching

- Automated optical inspection (AOI) and X-ray inspection systems

- Surface mount technology (SMT) and through-hole assembly lines

- Environmental testing and reliability labs

This infrastructure allows us to validate DFM recommendations in real production conditions, ensuring that our design guidelines are practical and effective.

4. Collaborative Customer Engagement

We believe that the best results come from strong collaboration. Our DFM process is not a one-time checklist but an ongoing dialogue with our customers. From initial design review to prototype validation and final production, we maintain open communication to address any concerns and implement improvements.

Our customers benefit from:

- Early-stage design consultations

- Rapid prototyping services

- Detailed DFM reports with visual annotations

- Engineering support throughout the product lifecycle

This collaborative approach not only improves manufacturability but also accelerates time-to-market and reduces overall development costs.

Real-World Impact: Case Study

To illustrate the value of our DFM process, consider a recent project with a client developing a high-speed communication module. The initial design featured tightly packed differential pairs and microvias, with minimal spacing between layers. While functionally sound, the layout posed several manufacturability challenges.

Our engineering team conducted a comprehensive DFM review and identified the following issues:

- Trace widths and spacing were below our standard fabrication limits

- Microvia aspect ratios exceeded recommended values

- Component placement interfered with automated assembly tools

We provided a detailed DFM report with suggested modifications, including adjusted trace geometries, relocated vias, and optimized component orientations. After implementing these changes, the client achieved:

- 15% reduction in fabrication cost

- 20% improvement in first-pass yield

- 30% faster assembly time

This case highlights how proactive DFM can lead to measurable improvements in both quality and efficiency.

Continuous Improvement and Future Outlook

As PCB technologies continue to evolve—with trends such as HDI (High-Density Interconnect), flexible and rigid-flex boards, and embedded components—DFM considerations are becoming increasingly complex. At UCREATE, we are committed to staying at the forefront of these developments.

We invest continuously in:

- Training our engineering teams on emerging technologies

- Upgrading our software tools and simulation platforms

- Expanding our manufacturing capabilities to support advanced designs

- Collaborating with industry partners and standards organizations

Our goal is to not only meet today’s DFM challenges but to anticipate tomorrow’s, ensuring that our customers remain competitive in a rapidly changing market.

Conclusion

In the realm of PCB manufacturing, design and production are deeply interconnected. A design that overlooks manufacturability can lead to delays, defects, and increased costs—while a design optimized for production can unlock efficiencies, enhance quality, and accelerate innovation.

At [Your Company Name], our robust DFM check process is a testament to our dedication to excellence. By combining technical expertise, advanced tools, and collaborative engagement, we empower our customers to bring reliable, high-performance products to market—faster and more cost-effectively.

Whether you are developing a simple single-sided board or a complex multilayer HDI design, you can trust us to guide you through every step of the DFM journey. Let’s build smarter, together.

English

English

中文

中文