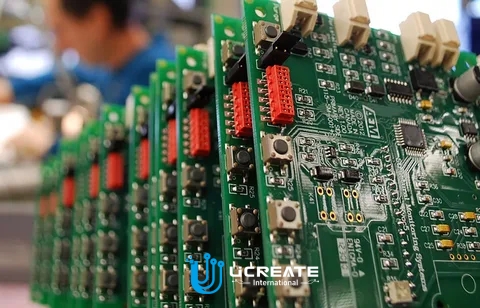

Quick PCB Assembly is an efficient and rapid production service model for circuit boards (PCBs), and its main features include:

1. Speed advantage.

In the production process, the fastest speed to complete the production process of circuit boards. For example, double-sided circuit board prototypes can be completed in a very short time, and small quantities can also be delivered in a very short time. This rapid production cycle allows companies to quickly respond to market demand, seize the market opportunity.

2. Technical guarantee.

Although the pursuit of speed, but quick PCB assembly service also focus on product quality. The use of advanced production technology and equipment, as well as a professional technical team to ensure that the rapid assembly at the same time, to maintain product stability and reliability.

3. Customised service.

We are able to provide personalised solutions according to the specific needs of our customers, such as product specifications, dimensions, quantities and so on. This flexibility allows quick PCB assembly to adapt to the specific needs of different companies.

4. Cost-effective.

While providing high-quality and efficient services, we also focus on cost control to ensure that customers can obtain quality services and products at reasonable prices. In summary, quick PCB assembly is a set of speed technology, customised services in one of the efficient production methods, designed to meet the needs of enterprises on the circuit board fast, accurate and personalised production. Through the professional technical team, advanced production equipment and optimised production process, we can ensure product quality while achieving rapid delivery, helping enterprises to enhance market competitiveness.

Before quick full PCB assembly, including quick PCB prototype assembly, you need to pay attention to the following points:

The design documents to prepare

1. Complete PCB assembly documents: provide complete PCB assembly documents, including the BOM bill of materials, Gerber files Pnp files, PCBA test files, etc., and to ensure that these documents are the latest version, updated in a timely manner to the manufacturer. Ucreate quick turn pcb manufacturer china provides free DFM test.

2. PCB manufacturing and assembly drawings: manufacturing drawings should include bare board specifications, such as drilling, hole diagrams, layer stacks and other information; assembly drawings should contain board assembly instructions, part shapes, parts lists and so on.

Component Selection and Layout

1. Segregation of leaded and lead-free components: Ensure that lead-free components are not mixed with components not designated for lead-free assembly to avoid soldering problems and compliance issues.

2. Component spacing: Follow proper component spacing rules, such as capacitors and resistors and other discrete components are spaced at least 10 mils apart, with 30 mils being the preferred spacing. This reduces potential problems caused by components being too close together.

3. Uniform placement of large components: Distribute large components as evenly as possible on the PCB during layout to achieve better heat distribution during reflow.

Technical details and requirements

1. Clear and legible silkscreen: Ensure that the silkscreen markings are clearly visible in order to correctly indicate component position, polarity and other key information during assembly.

2. Identification of component polarity: clearly identify the cathode and anode, as well as the position of pin 1 on components such as electrolytic capacitors, LEDs, diodes and ICs to prevent errors during assembly.

Quality control and testing

Post-assembly inspection and testing: After completing the PCB assembly, visual inspection, automatic optical inspection (AOI), functional testing and so on must be carried out to ensure the quality and performance of the circuit.

Customised services

Meet the special needs: according to the specific needs of customers, such as product specifications, size, quantity, etc., to provide personalised PCB prototype assembly solutions.

Production efficiency

Optimisation of production processes: Improvement of production efficiency through optimisation of production processes and the use of advanced production equipment and technology to achieve rapid delivery.

In summary, quick PCB prototype assembly requires attention to design file preparation, component selection and layout, technical details and requirements, quality control and testing, customisation and production efficiency. By ensuring that these key points are executed correctly, the rapid, accurate and reliable assembly of PCB prototypes can be ensured.

English

English

中文

中文